Views: 0 Author: Sunny Yu Publish Time: 2025-10-11 Origin: Site

In packaging and logistics, efficiency isn't just a buzzword — it's a lifeline. When you're moving tons of product day in and day out, every second counts. Downtime, misfeeds, seal failures — these all chip away at your bottom line. That’s why automated solutions and high-throughput components are critical.

Consumers expect faster delivery. E-commerce, global supply chains, just-in-time manufacturing — all push for faster packaging lines. Manual operations just can’t keep up in large scale.

Think of it: a few seconds delay per package, over thousands of packages, becomes hours of lost productivity. Add in human error (mis-placed seal, improper alignment) and you’ve got rework, wasted materials, and frustrated teams.

Automated strapping solutions reduce those weak links. But to fully deliver, every piece — strap, tool, seal — must pull its weight. That’s where a quality magazine seal becomes a game changer.

A magazine seal (or magazine strapping seal) is a seal designed to be stacked or nested in a magazine or feed carriage, allowing automatic feeding into the strapping tool or machine. The tool advances the seal stack so each seal is ready to be applied without manual placement. It’s like having a supply line of seals ready to go — no one has to grab one by hand.

Traditional seals — snap-on, open-flange, push, thread-on — often require manual placement or alignment per seal. Magazine seals, by contrast, are prearranged, indexed, and fed automatically. That removes the per-seal manual movement, reduces errors, and stabilizes speed.

Snap-On: operator or tool “snaps” the seal on overlapping strap ends. Simple but limited in speed.

Push / Closed: tool pushes seal over strap, deforming it to lock. Strong but often manual or semi-automatic.

Open-Flange: gives extra side stability, useful for lateral forces.

Serrated: features internal teeth for better grip, especially on plastic straps (PET/PP).

Magazine: stacked, interlocking, fed automatically. Best for high efficiency / high volume lines.

Snap on seal

Push type seal

Open flange seal

Serrated seals

Magazine seal

Serrated seal

we dive deeper into magazine seals, serrated seals, and closed (push-type) seals, showing how each is used in real operations — and providing a video to see them in action.

Magazine seals are stacked interlocking seals designed for automatic feed in strapping machines. Their major advantage lies in enabling continuous operation with minimal manual intervention. Typical applications include:

High-speed pallet strapping lines

Inline conveyor systems

Automated arch or side-seal machines

High output packaging plants with minimal downtime

Because magazine seals are popped from a magazine or feed carriage, they drastically reduce delays between seal placements and improve consistency.

Serrated seals (sometimes called tooth seals) feature internal teeth that bite into the strap surface for enhanced grip. They are commonly used with plastic strapping (PET / PP) rather than steel strapping. Key points:

The teeth improve friction and prevent strap slippage under vibration or load stress

They are especially helpful when straps are subject to dynamic stress or shock

Many packaging tool makers provide matching serrated seals + sealers to optimize the bite

Closed or push-type seals (also sometimes called sleeve seals) are engineered for steel strapping & heavier loads. The tool pushes the seal over the overlapped strap ends, deforming it to lock them securely. Their benefits:

Provide a fully enclosed seal with strong mechanical lock

Often more tamper-evident and harder to remove without damage

Suitable for coils, pipe bundles, or heavy structural loads

In many steel strapping applications, closed seals are preferred when a robust, permanent lock is required.

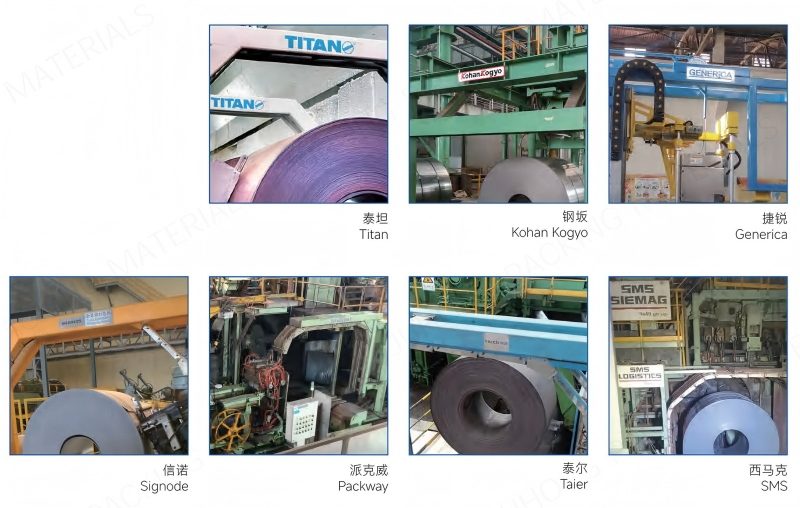

Juhong offers magazine seals that are engineered to be compatible with a wide range of fully automatic strapping machines — arch machines, inline systems, side-seal machines, you name it. Their dimensions, stack geometry, and feed tolerances are optimized to match the mechanics of popular global machines.

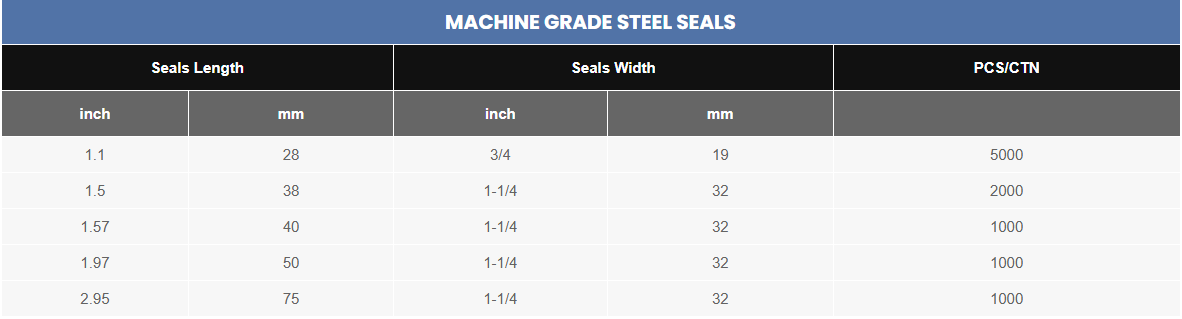

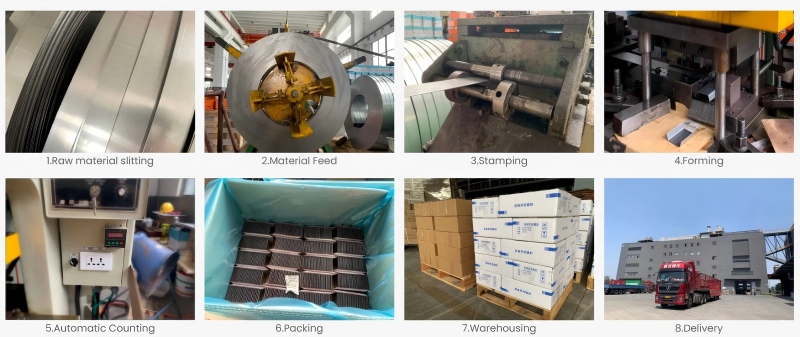

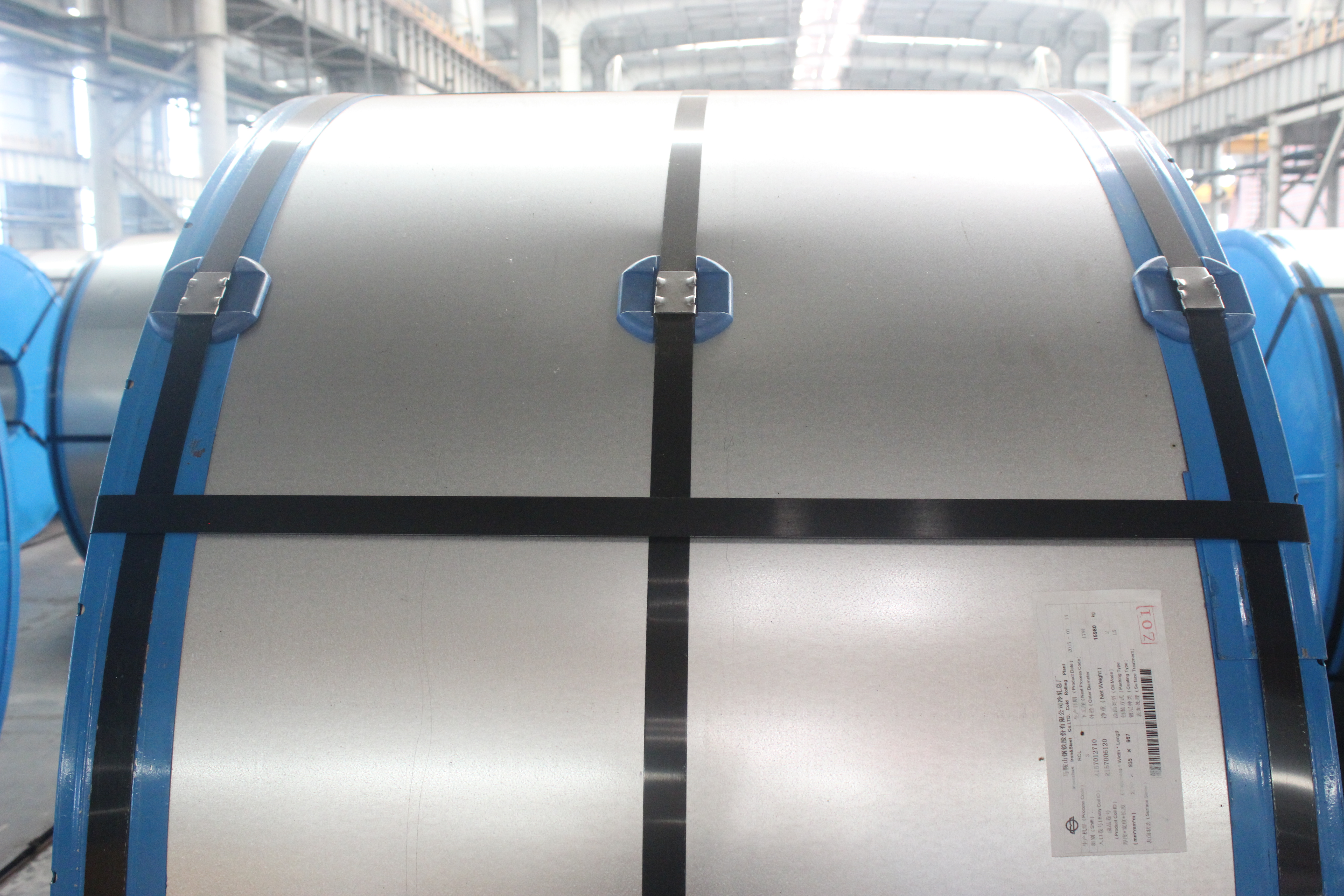

Constructed from high-quality steel , Juhong’s magazine seals often carry corrosion-resistant coatings — galvanizing, zinc plating, or specialized treatments. They are tested for bite strength, fatigue, and cycle stability. Each batch undergoes quality control to maintain tight tolerances.

Brand identity matters. Juhong offers logo stamping on seals, so your brand travels with each package. They also provide packaging customization — custom cartons, counts, labeling — to give your customer a more polished experience.

One of Juhong’s standout strengths is its deep integration into industry standards and innovation. The company is one of the drafting units for China’s national standard“Steel Seals & Edge Protectors for Packaging” (GB/T 39040-2020).std.samr.gov.cn,Their contributions to standards development show significant influence and technical recognition.

Moreover, Juhong’s independently developed high-strength alloy strapping and locking buckles have been certified as High-Tech Products. The company holds 35 valid intellectual property rights, among which 22 are invention patents.jhstrapping.com.These credentials are not just badges — they underpin Juhong’s engineering muscle, giving credibility when clients evaluate alternatives to legacy systems.

Their seals drop into existing systems with minimal adjustment. Because they match the feed geometry and stack behavior, you don't need to reengineer your equipment just to use their seals.

Designed for thousands to tens of thousands of cycles, Juhong’s magazine seals resist fatigue, misfeeds, and jamming. The consistent tolerances reduce variation in feeding behavior over long runs.

They aim not to be the cheapest seal but the best value seal. Over life cycle costs — fewer stoppages, reduced wasted seals, smoother operations — Juhong’s seals pay for themselves.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

These industries demand strong, reliable sealing under extreme weight and vibration. Magazine seals shine here — rapid, consistent sealing reduces cycle time and bottlenecks.

In fast pallet lines for consumer goods, throughput is king. Every second saved in seal placement counts. Magazine seals speed up the process while maintaining strength.

Juhong’s magazine seals are engineered for compatibility with the majority of automatic strapping machines on the market. They deliver seamless integration, robust performance, and exceptional value—making them the high-efficiency choice for automated packaging systems.

Always start by gathering your machine’s seal specification: stack height, feed pitch, seal width, nib spacing, etc. Ensure the replacement magazine seal matches closely.

Fine-tune feed motors, tensioners, and guides. If the feed is too aggressive, seals may jam. Too loose, and misfeeds occur. Test slowly before ramping up.

Regular cleaning, checking for burrs, inspecting feed paths — all good habits. Watch for signs of misalignment, double feeds, or seal drag, and correct them early.

When you request samples, include your machine brand/model, preferred seal dimensions, stack parameters, and operating speed. The more detail, the better match you’ll get.

Run the seals side by side with your current ones. Monitor misfeeds, downtime, defect rates. Keep a log. If results stay within acceptable margins (or better), you've got a winner.

Imagine seals with miniature trackers, sensors, or RFID tags — able to report tension, detect loosening, or log transport history. These “smart seals” could become standard for high-end or critical shipments.

Expect lighter alloys, nano-coatings, self-lubricating surfaces, or hybrid composites. These innovations aim to reduce friction, improve wear resistance, and maintain strength.

High-efficiency strapping demands every component deliver — and seals are no exception. Juhong’s magazine seals bring compatibility, robustness, and brand customization together in a package that’s worthy of modern, high-volume lines.

If your operation uses automatic strapping machines and you’d like to see how Juhong’s magazine seals perform in yours, we invite you to request sample sets matched to your specifications. Let’s run trials, compare metrics, and help you make the switch with confidence.