Views: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

Why the seemingly simple strapping clip or seal is critical to supply chain integrity.

When you think about the complexity of global logistics, your mind likely jumps to the massive shipping containers, fleets of trucks, or the intricate networks of warehouses. However, in the background of all these operations, there is an often-overlooked yet vital component—the strapping seal. Whether it’s securing a heavy load of steel beams in a construction project or protecting delicate electronics in transit, the banding clip or strapping seal plays a pivotal role in ensuring that goods stay intact, secure, and delivered safely to their destination.

“Banding Clips” (also known as Strapping Seals or Steel Seals) ,At its core, a banding clip (or strapping seal) is a fastening device used to secure strapping around a load. This seemingly simple component works in tandem with other packaging tools, such as strapping machines, to bind and secure goods for transportation. These seals lock the strapping in place, preventing movement and ensuring that the package remains stable throughout its journey, whether by road, sea, or air. The choice of strapping seal manufacturer is crucial to the success of any logistics operation. While many suppliers provide these essential components, the best manufacturers not only have a global reach but also innovate with cutting-edge technologies, ensuring that their products meet international standards. This article aims to reveal the top 8 global banding clips and strapping seals manufacturers who are at the forefront of the industry, shaping the future of secure packaging.

Steel Strapping Seals

Plastic Strapping Seals

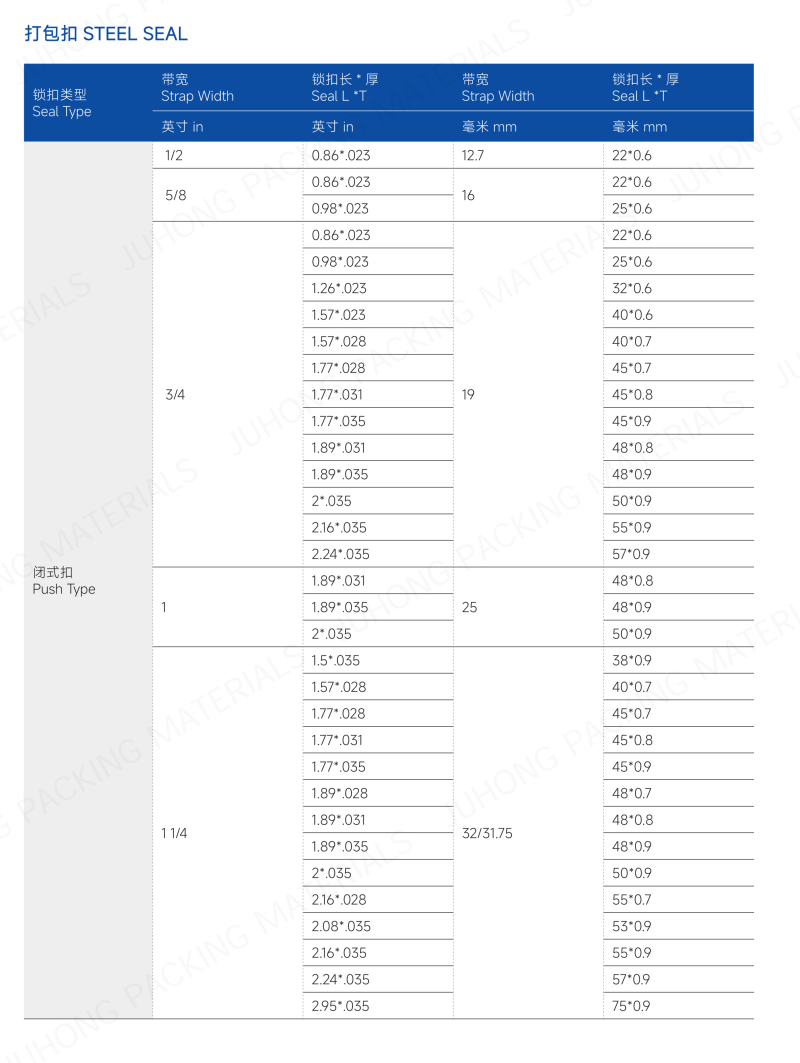

When you think of heavy-duty strapping, steel strapping seals come to mind. These clips are designed for metal banding and are typically used in industries such as construction, steel manufacturing, and shipping where strong, reliable fastening is required. There are several types of metal banding clips, including closed/pusher seals, snap-on seals, and open seals, each designed for different applications. For instance, closed seals are ideal for high-tension applications, while snap-on seals are used for quick and efficient sealing during manual strapping. These seals provide a secure hold and prevent slippage, offering high resistance to heavy loads and harsh conditions.

For lighter-duty applications, plastic banding clips are often used, especially with PET (polyester) and PP (polypropylene) strapping. These seals are less expensive and lighter than their steel counterparts, making them a popular choice in packaging industries that don’t need the extreme strength of steel. Polyester strapping seals provide a reliable hold and are resistant to environmental factors such as moisture and UV rays. While plastic seals may not offer the same tensile strength as steel, they are suitable for less demanding applications and are often used in retail packaging and logistics for smaller loads.

Specialized Seals for Automation: As the logistics and packaging industries continue to innovate, traditional sealing methods are evolving. The future of strapping seals lies in proprietary sealing systems—patented clip designs that enhance the efficiency of automated strapping machines. These advanced sealing systems are designed for high-speed production lines, where traditional manual methods simply don’t cut it. Specialized clips are engineered to improve both safety and speed, ensuring that packaging operations can keep pace with modern automation demands. Innovations such as magazine seals—which allow for high-volume strapping—are leading the way in transforming how goods are packaged and secured at the industrial level.

When it comes to banding clips and strapping seals, the global market is driven by a few key players who dominate the landscape. Let’s take a closer look at the top 8 manufacturers shaping the industry today.

Website:www.signode.com

Signode is a market leader in industrial packaging, offering a complete range of strapping, tools, and seals. The company is known for its global reach and innovation, particularly in automation. Signode’s strapping seals are widely used in industries ranging from automotive to construction, and their products are compatible with both manual and automated strapping systems. Their reputation for high-quality materials and commitment to technological advancement makes them a dominant force in the global market.

Website:www.fromm-pack.com

Fromm is another top manufacturer of banding clips and strapping products. They offer both steel and plastic strapping seals, catering to a wide array of industries, including food packaging, pharmaceuticals, and logistics. With a strong presence in both Europe and North America, Fromm is known for its innovation in automation and continuous investment in advanced strapping technologies.

Website:www.samuelpackaging.com

Samuel Strapping Systems has been a significant player in the global metal strapping and sealing industry for over 30 years. They specialize in high-tensile steel strapping seals and offer a broad range of packaging tools. Their products are renowned for strength and durability, particularly in heavy-duty applications like steel mills and construction.

Website:https://greenbridge.com

Greenbridge manufactures High-quality steel strapping, PET, and PP strapping solutions, along with packaging accessories such as strapping tools and seals.Greenbridge has recently gained significant traction in the market, particularly in North America and Europe. Known for offering eco-friendly alternatives, Greenbridge stands out by integrating sustainable practices into their production processes. The company emphasizes recyclable materials and focuses on offering high-strength packaging products designed to meet both industrial and environmental standards.

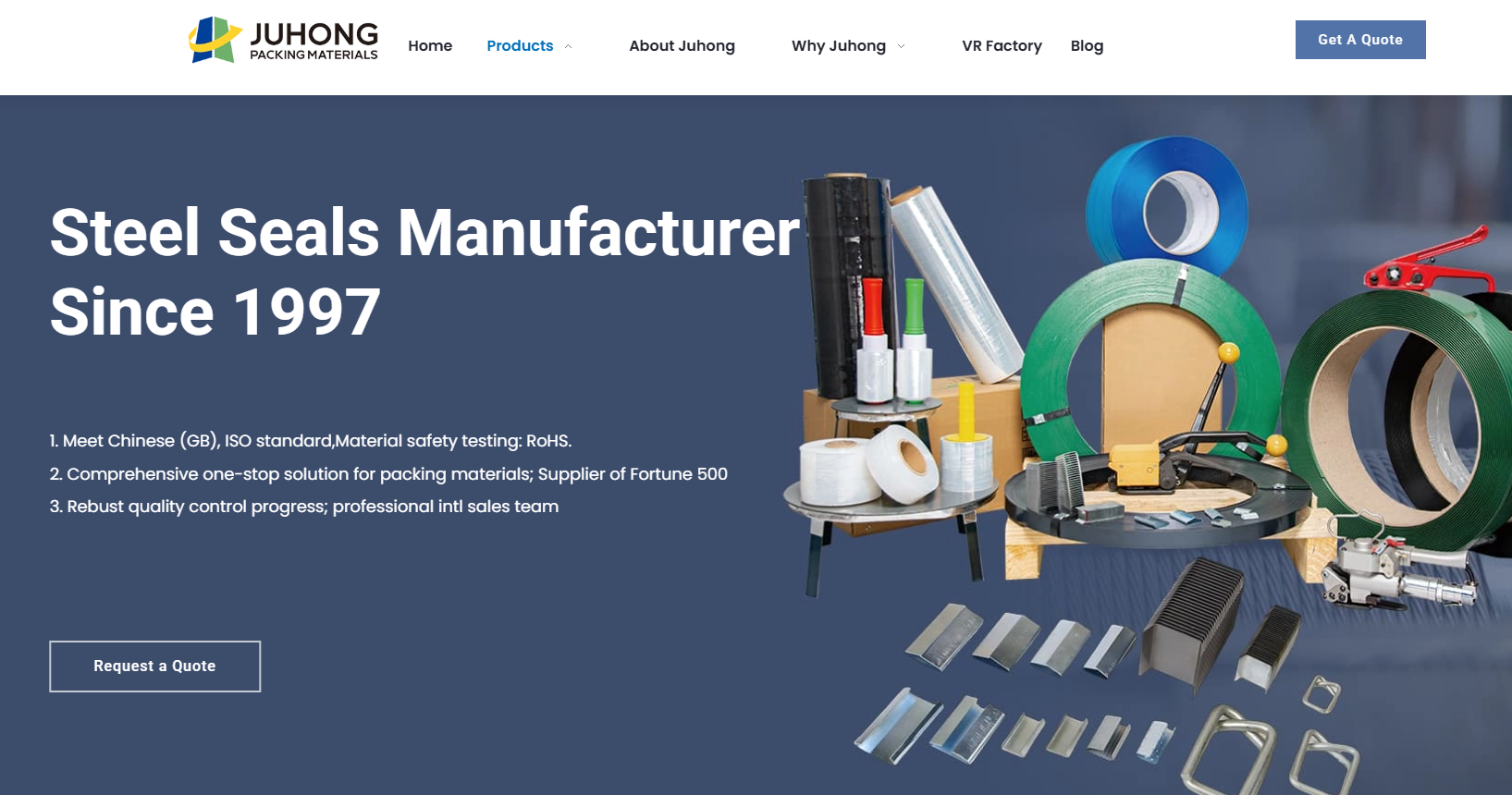

Website:www.jsjhpackaging.com

Juhong Packing Materials is an industry leader in strapping seals and banding clips with a unique edge. As the key drafting unit of the National Standard GB/T 39040—2020, Juhong is at the forefront of technical innovation, especially with their magazine seals. These patented designs significantly improve the speed and efficiency of automated strapping machines, enabling businesses to boost productivity while maintaining the highest standards of safety and integrity.

•Primary Product Focus: Stretch Film,Steel strapping and plastic strapping, with patented innovations like the magazine seals for high-speed automation.

•Global Presence: As a leader in the Asian market, Juhong is also expanding its footprint globally, particularly in industries requiring high-strength and automated strapping solutions.

•Customization: Juhong offers customized logo services for our strapping seals. This allows you to add your brand identity to our seals, providing a professional and personalized

touch for your packaging needs. Whether you require bulk production or small batch runs, we ensure high-quality, consistent results that help reinforce your brand while maintaining

the integrity and security of your packaging.

Website:https://www.maillis.com/

MJ Maillis Group With a strong European presence, Maillis serves a broad global market with advanced automation and packaging technology.

Product Focus: Steel and plastic strapping systems, strapping tools, and related packaging machinery.

Website:https://strapack.com/

StraPack is a key player in the automated packaging sector, offering both plastic and steel strapping seals. The company focuses on integrating advanced automation with high-performance sealing systems, creating solutions that streamline the packing process for industries with high volume needs. StraPack is particularly well-regarded for its efficient, user-friendly machines that work seamlessly with their strapping seals.

Website:https://www.mosca.com/

Mosca is a leader in end-of-line packaging systems, offering an extensive range of banding clips and strapping seals. Known for their high-speed automated machines, Mosca’s products are designed to meet the needs of industries that require rapid packaging and secure strapping for large quantities of goods. Their solutions are used extensively in logistics, food processing, and retail packaging.

Patented Technology (The Magazine Seals) At Juhong, innovation is at the heart of everything we do. Our magazine seals, a revolutionary invention, have transformed the packaging and logistics industry by enhancing automation. This patented solution significantly boosts the efficiency of high-speed automated strapping systems, allowing businesses to streamline their operations without sacrificing reliability or security.

The clip-magazine design enables faster, smoother sealing processes, reducing downtime and increasing overall productivity. By eliminating the need for manual handling, our patented technology helps companies save time and reduce labor costs, making Juhong’s seals the go-to choice for high-volume industries worldwide.

Standards Authority Juhong’s expertise doesn’t stop at innovation. As a drafting unit for the National Standard GB/T 39040—2020, we play a crucial role in shaping the future of strapping seals and packaging materials. Our commitment to compliance and standards ensures that all of our products meet stringent quality requirements, making us a trusted partner for businesses seeking reliable, standards-driven packaging solutions.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

When choosing a strapping seals supplier, it’s essential to evaluate several key factors to ensure that you’re partnering with a reliable, innovative, and compliant company. Here are the main criteria to consider:

Compliance and Technical Authority Choosing a supplier involved in setting industry standards is vital. Juhong’s role in drafting the GB/T 39040—2020 standard ensures that our products adhere to the highest levels of quality and compliance, providing you with the confidence that our strapping seals meet or exceed international standards. When selecting a supplier, ensure they are familiar with and follow established technical specifications, such as ASTM D3953 for steel strapping. Adherence to these standards guarantees that your packaging materials will perform reliably and safely under demanding conditions.

Manufacturing Capability and Supply Chain Manufacturing capacity is another critical factor to consider when choosing a supplier. A supplier with high production capacity and stable supply chains can ensure that your business never faces delays due to shortages. This is especially crucial for industries with continuous or high-volume packaging needs. Companies like Juhong that have the ability to produce specialized, patented products, such as our magazine seals, can offer an added advantage by meeting unique operational requirements. Additionally, a robust supply chain is essential for ensuring timely deliveries and maintaining stock levels to meet fluctuating demands.

Automation and Compatibility As automation continues to shape the packaging industry, selecting seals that are compatible with modern, high-speed tools is a must. Suppliers should offer products designed specifically for use with automated strapping machines and strapping tools. At Juhong, our magazine seals are specifically engineered for high-speed automation, Compatible with KOHAN /Signode/KOGYO/Titan/SMS/Generica/Sund Birsta ,for use with steel strapping. By choosing a supplier that invests in automation-friendly designs, you ensure that your business is well-equipped to handle the future of packaging technology.

The packaging industry is constantly evolving, driven by advances in technology and an increasing demand for sustainability. Looking ahead, we can expect a few key trends to shape the future of strapping seals:

Sustainability: As environmental concerns grow, manufacturers are focusing on eco-friendly materials and sustainable practices. We can expect to see a rise in biodegradable or recyclable strapping materials that still offer the same level of security and strength.

Smart Packaging: With the rise of IoT (Internet of Things), smart packaging solutions will likely play a role in the future. We may see intelligent strapping seals that provide real-time monitoring of the goods they secure, offering insights into packaging integrity and improving supply chain visibility. As the industry continues to innovate, Juhong Packing Materials will remain at the forefront, providing cutting-edge solutions designed for tomorrow’s packaging needs. Together, we can secure a future of reliable, efficient, and sustainable logistics.

As we have explored throughout this article, the seemingly simple strapping seal plays an essential role in the global logistics and packaging industry. From securing heavy loads to ensuring safe delivery, the quality and innovation behind these components directly impact the efficiency, safety, and reliability of the entire supply chain. By partnering with the best manufacturers in the business—companies like Signode, Fromm, Samuel,Greenbridge Packaging, Juhong, and others—you can be confident that your packaging needs are in good hands. Each of these global players has a proven track record of delivering quality products that meet the rigorous demands of industries worldwide. And while many of them offer similar products, it is companies like Juhong that are leading the charge in innovation, with patented solutions like our magazine seals that set new benchmarks for automation, speed, and efficiency.

If you’re looking for a partner who not only meets the industry’s standards but also shapes them, Juhong Packing Materials is the solution. As the key drafting unit for the National Standard GB/T 39040—2020, we offer patented sealing technology designed to optimize your operations. Partner with Juhong today to ensure your packaging meets and exceeds the highest standards of safety and efficiency, all while boosting your productivity with our revolutionary magazine seals.

If you need a customized quotation or have any questions, to learn how our products can enhance the security of your supply chain, please contact us.