Views: 0 Author: Sunny Yu Publish Time: 2026-01-28 Origin: Site

In heavy-duty industrial packaging, the efficiency of your production line is often dictated by the winding method of your steel strapping. Choosing between Ribbon Wound (RW), Oscillated Wound (OW), and Jumbo Coils (JC) is not just a matter of preference—it affects your equipment compatibility, labor safety, and overall operational downtime.

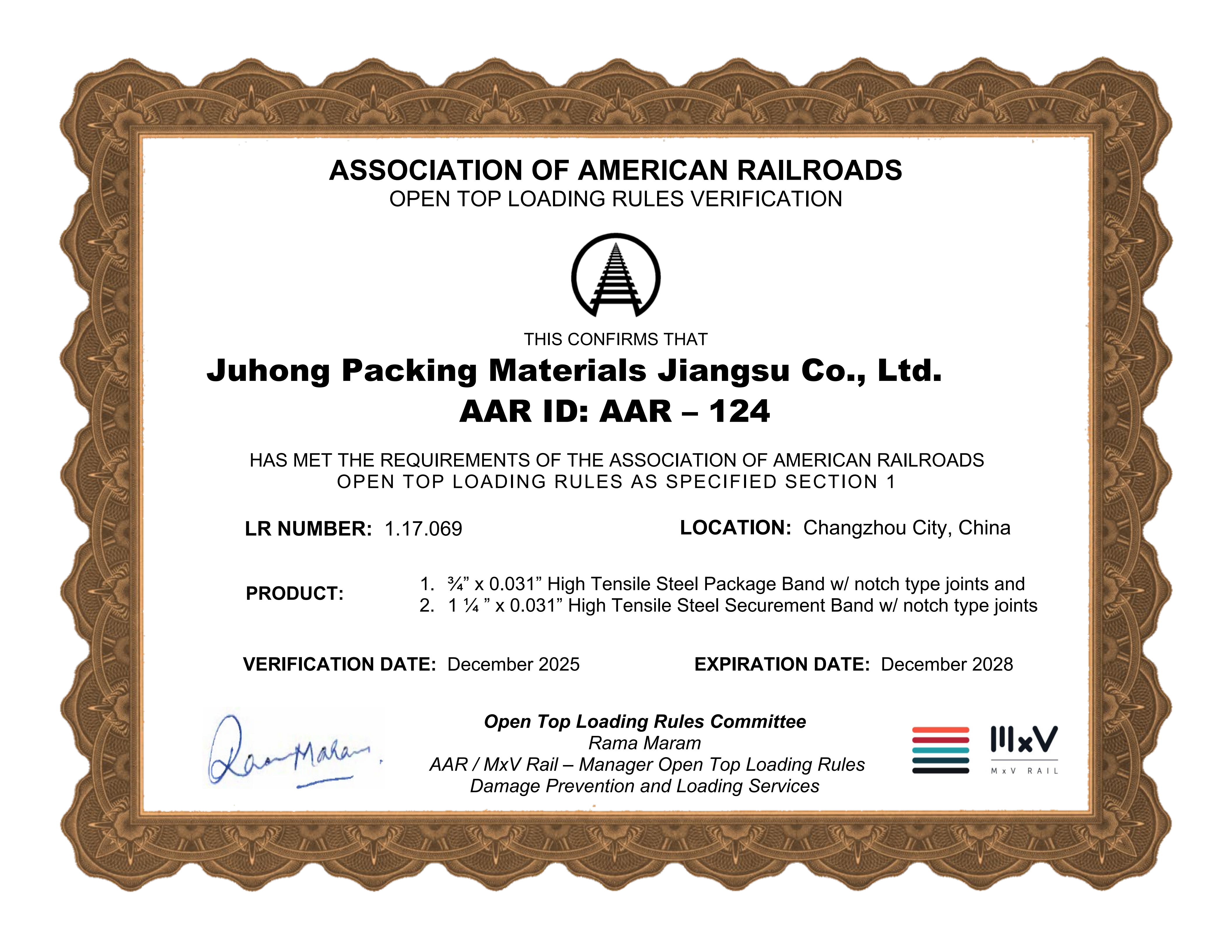

As a leading manufacturer, Juhong Packing Materials provides AAR-certified strapping solutions engineered for the most demanding global logistics environments.

Ribbon Wound

Ribbon Coil Size

Blue Steel Strap

Ribbon winding (also known as Single Wound) is the traditional method where the strap is wound onto itself so the coil width is identical to the strap width.

Coil Weight: Typically ranges from 25kg to 50kg (55–110 lbs).

Core ID Options: Available in 200mm, 300mm, or 406mm diameters.

Best Use Case: Ideal for manual applications and mobile strapping tasks using pneumatic or manual tools.

Oscillated Wound

Oscillated Coil Size

Black Painted Steel Strap

Oscillated winding (Mill Wound) involves winding the strap back and forth across a wider core, similar to a spool of thread.

Extended Length: By oscillating the strap, a single coil contains significantly more footage than a ribbon coil.

Standard Weight: Generally maintained at 40kg to 50kg (88–110 lbs) for easier handling.

Core Diameter: Standardized at 406mm for compatibility with semi-automatic dispensers.

Jumbo Coil

Jumbo Coil Size

Jumbo Galvanized Steel Strap

For high-capacity, fully automated production lines, Jumbo Coils represent the pinnacle of winding efficiency.

Massive Weight Capacity: Available from 180kg up to 600kg (396–1322 lbs).

Dimensions: Coil widths range from 192mm to 400mm with an outer diameter of 700mm to 900mm.

Downtime Reduction: One Jumbo coil can replace up to 12 standard ribbon coils, drastically reducing the frequency of machine stops.

| Feature | Ribbon Wound | Oscillated Wound | Jumbo / Super Jumbo |

| Standard Weight | 25–50 kg | 40–50 kg | 180–600 kg |

| Coil Width | 13-32mm | 63.5mm | 192-400mm |

| Core ID | 200/300/406 mm | 406mm | 406/610 mm |

| Automation Level | Manual/Pneumatic | Semi-Automatic | Fully Automated |

Signode Packaging Systems

Generica automatic strapping system

Kohan Kogyo Automatic Strapping Machine

SMS Group Fully Automatic Coil Packaging Line

FROMM Pneumatic Tool

Packway Automatic Strapping Machine

The winding method you select must align with your machinery's dispensing capabilities.

Juhong steel strapping is precision-engineered to be compatible with world-leading strapping heads and systems:

High-End Systems: Signode, Titan, and Kohan Kogyo.

Automated Lines: Packway, Taier, SMS, and Generica.

Seal Joint

Spot-weld sealless joints

Die-cut sealless joints

Our strapping supports multiple joint technologies to ensure maximum seal strength:

Seal Joint: Traditional high-security strapping.

Sealless Technology: Including Spot-weld and Die-cut sealless joints for improved efficiency.

Juhong Packing Materials' products are AAR (Association of American Railroads) certified. This certification is essential for any cargo transported via rail in North America, guaranteeing the strapping can withstand extreme shifting and tension.

Our manufacturing process adheres to rigorous global benchmarks to ensure consistency:

Standard Compliance: GB, EN, ASTM,ABNT NBR and JIS.

Surface Finishes: Options include Bright, Blue Tempered & Waxed, Painted & Waxed, and Galvanized for superior corrosion resistan.

Safety Engineering: Every strap features smooth, de-burred edges to protect workers from manual handling injuries.

Our high-tensile strapping is the primary choice for securing:

Steel coils and pipes.

Non-ferrous ingots (Electrolytic Copper, Aluminum).

Beyond metal, Juhong provides reliable securing for:

Lumber and Glass: Precision tensioning to prevent breakage.

Global Logistics: Export-ready packaging with VCI anti-rust paper and waterproof protection.

Whether your facility requires the portability of Ribbon winding or the industrial scale of 600kg Jumbo coils, Juhong Packing Materials delivers the certified quality your business demands.

Ready to optimize your packaging line? explore our full technical catalog at www.jsjhpackaging.com.

Take the Next Step: Juhong Packing Materials' 2026 Brochure.pdf

Juhong Packing Materials' 2026 Brochure.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

AAR Certified Juhong High-Tensile Steel Strapping Document.pdf

AAR Certified Juhong High-Tensile Steel Strapping Document.pdf

Ribbon vs. Oscillated vs. Jumbo: The Definitive Guide to Steel Strapping Winding Methods

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America