Views: 0 Author: Sunny Yu Publish Time: 2025-08-12 Origin: Site

Picture this: You’ve shipped a $50,000 industrial generator. Halfway across the ocean, the strapping snaps. Saltwater seeps in. The customer receives a corroded paperweight. Nightmare fuel, right? Choosing steel strapping isn’t just picking "metal tape" – it’s selecting the guardian of your cargo. Get it wrong, and you risk financial bleed, reputational damage, and safety hazards. Get it right? You sleep soundly knowing your load survives hurricanes, rough handling, and 6,000-mile journeys. Let’s make sure you nail this.

Authority Statement: Selecting the wrong strapping can lead to catastrophic load failure. As the Lead Drafter of China National Standard GB/T 39040-2020, Juhong understands that load security depends on the perfect synergy between the strap and the strapping seals.Juhong Packing provides this technical guide to help you match your load requirements with international standards like ASTM D3953,EN and AAR mandates.

Short on time?If you already know your specifications and are looking for a reliable manufacturer, skip this guide and view our Factory-Direct Steel Strapping Catalog & Specs directly. We offer ISO-certified quality with competitive wholesale pricing.

Think of it as the Hulk of the packaging world. It’s a high-tensile steel strappingcoiled up like a snake, ready to constrict your heaviest loads. Unlike its cousin PET strapping, steel laughs at sharp edges, extreme weights, and scorching heat.

Ever tried tying down an I-beam with duct tape? Yeah, don’t. Steel strapping delivers unbeatable:

Tensile Strength: Handles insane tension (up to 1,500 kg/mm²!).

Rigidity: Zero stretch means zero load shift.

Heat/Chemical Resistance: Survives foundries, chemical plants, and desert crossings.

Before selecting a strap, define your load's "personality." Steel strapping is the ultimate choice for:

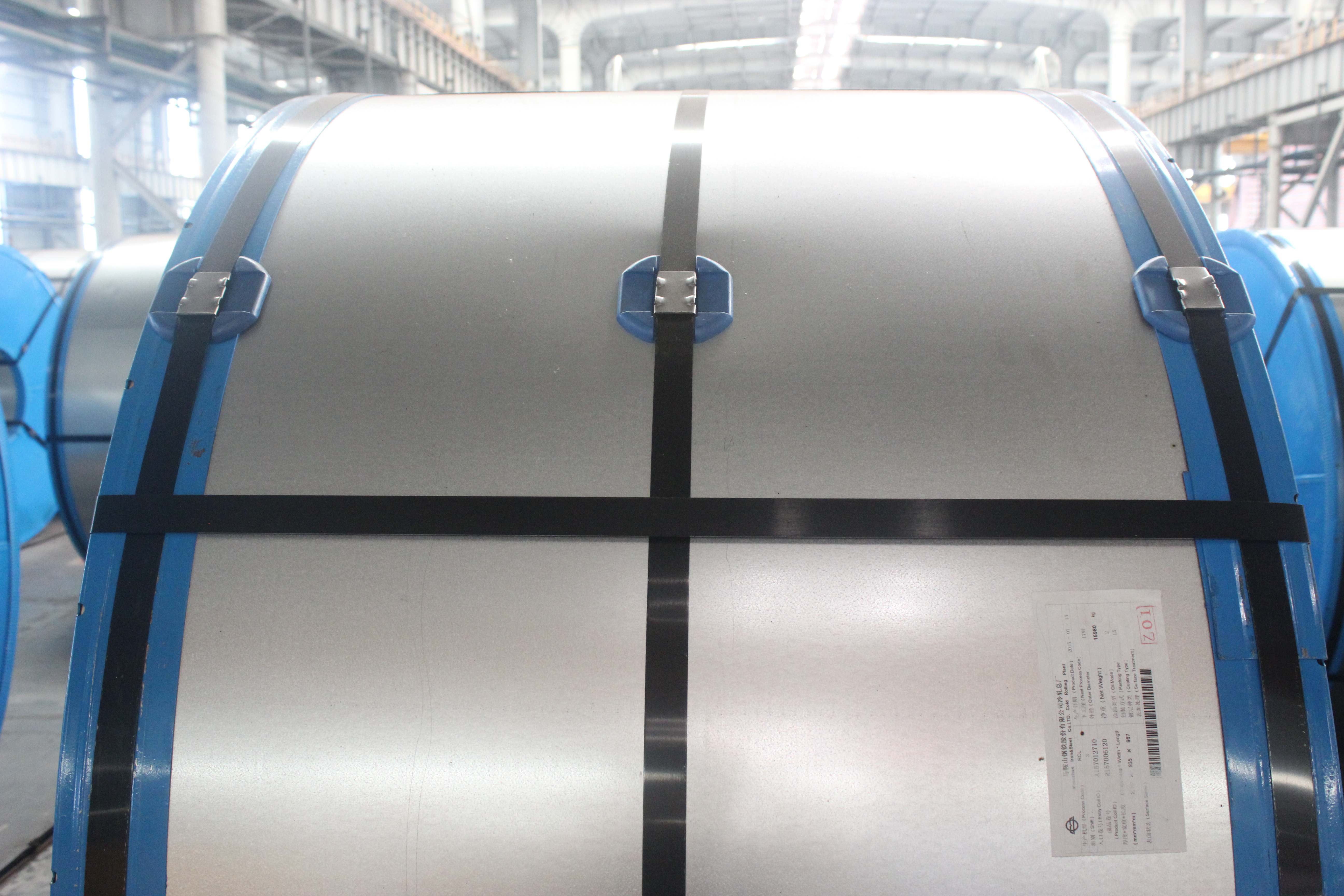

Heavy-Duty Bundling: Specifically for steel coils, aluminum ingots, and heavy machinery.

Extreme Environments: Unlike PET, steel strapping maintains tension in temperatures exceeding 500°C.

Zero-Creep Logistics: For rigid loads that cannot allow for any strap stretching during long-haul maritime transit.

Your provided data shows a high search volume for "high tensile." Understanding the difference is vital for safety:

Process: Cold-rolled, high-carbon steel, specially heat-treated.

Best For: Railroad shipments (AAR approved), heavy metal strapping for steel plates, and high-impact shock resistance.

Strength range: 900–1000+ MPa.

Process: Low-to-medium carbon steel with superior elongation.

Best For: Standard palletizing, brick bundling, and light-to-medium industrial packaging.

Strength range: 650–880 MPa.

Painted & Waxed (Black): The most common finish. The waxed steel strapping coating reduces friction, allowing the strap to tension uniformly around sharp corners.

Zinc-Coated (Galvanized): Provides the highest corrosion resistance. Essential for goods stored outdoors or facing salty sea-freight environments.

Blued & Waxed: A chemical treatment offering basic rust resistance for indoor storage.

Not all steel is created equal. This is where JUHONG Packaging Materials shines – they offer tailored solutions:

Low-Carbon (e.g., ATSM D3950 ): More flexible, easier to tension. Perfect for lighter loads (<1 ton) like bricks or palletized boxes.

High-Carbon (e.g., ASTM D3950 ): The Hercules of strapping. Handles brutal tension for machinery, pipes, or timber.

Common steel strips usually have bright steel strapping、blue steel strapping、painted & waxed steel strapping、and galvanized steel strapping.

Bright steel strapping is cold rolled,process without heat treated and metal surface.

Blue Tempered & Waxed steel strapping adopts a special non-leadheat treatment process,At the same time, the formation of bluing film on the surface of the steel strapping and then coated a layer of water wax to form the double protection.

Bare steel rusts faster than a bike left in the rain. Coatings are non-negotiable:

Galvanized (Zinc-Coated) steel strapping: cold rolled and a layer of zinc Hot dip plating on the surface,JUHONG’s MVP for humid or marine environments. solves the common problem of the steel strapping in a short term play the role in anti-corrosion.Ideal for export shipping containers.

Painted (Green/Black)& Waxed steel trapping: a high-quality coating with a uniform wax seal, delivering dual defense for exceptional corrosion resistance. Widely applied in demanding environments for bundling, securing, and transporting goods, it ensures safety and reliability.

Precision in sizing is the cornerstone of packaging reliability. As the lead national standard drafter, Juhong adheres to a strict width tolerance of ±0.1mm and a thickness tolerance of ±0.035mm.

This level of dimensional accuracy is critical for ensuring seamless compatibility with your equipment. It effectively prevents costly downtime caused by jams in high-speed automatic steel strapping tools and ensures that every strapping seal fits perfectly, maintaining the structural integrity of your load-bearing system.

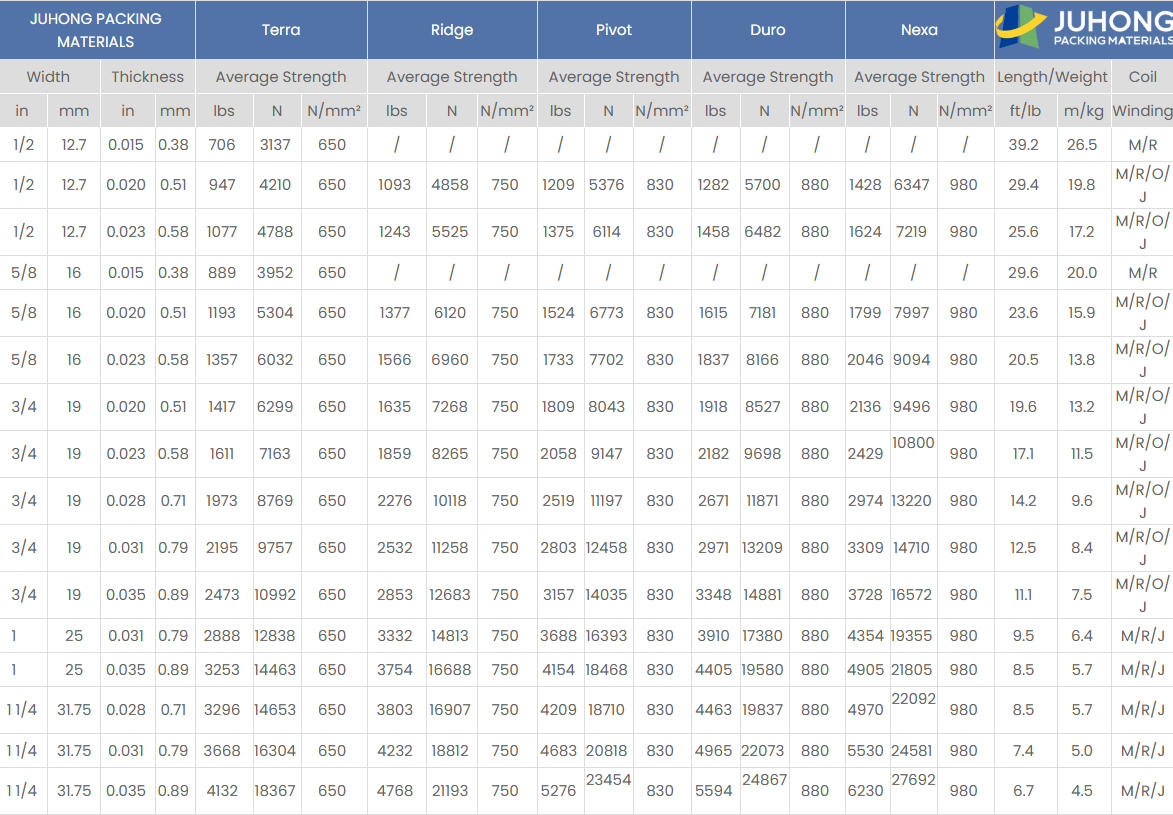

| Size (Width x Thickness) | Grade | Breaking Strength (Lbs) | Tensile Strength (MPa) | Industrial Application |

| 1/2" x 0.020" | Regular Duty | ~1,282 lbs | ~880 MPa | Light palletizing & small crates |

| 5/8" x 0.023" | Regular Duty | ~1,837 lbs | ~880 MPa | Medium industrial packaging |

| 3/4" x 0.023" | Regular Duty | ~2,182 lbs | ~880 MPa | Timber, bricks, & standard metal bundles |

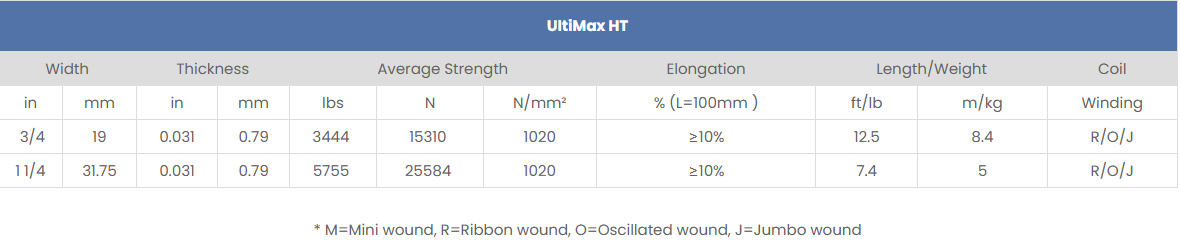

| 1-1/4" x 0.031" | High Tensile | ~5,650 lbs | ~1020 MPa | Hot-rolled steel coils & heavy pipe |

| 2" x 0.047" | High Tensile | ~8,400 lbs | ~1,020 MPa | Heavy machinery & 2-inch wide strapping needs |

To achieve the maximum breaking strength listed above, you must use high-compatibility heavy-duty strapping seals. A mismatched seal can reduce system integrity by up to 50%.

Width (12mm-32mm): Wider = more surface area = less cutting into soft loads (timber, pipes).

Thickness (0.4mm-1mm): Thicker = higher break strength.

If you are not sure about how to choose the size, you can contact the experts of JUHONG. They will provide you with technical support.

According to the tensile strength grade of the steel belt, we can be divided into the regular standard and the high tensile steel strapping.

The tension grade varies depending on the country, and the standards set accordingly aslo differ. If you need high-strength steel strips, you must ask him whether they can meet the ASTM standards. Or you should clearly inform the manufacturer of the specific tension level you require.

Tensile Strength: How much force until it snaps ( N/mm²).

Elongation: How much it stretches before breaking

The standards for steel strips used in packaging in China.pdf

The standards for steel strips used in packaging in China.pdf

Standard for packaging steel straps in the United States.pdf

Standard for packaging steel straps in the United States.pdf

Engineer's Recommendation:For heavy-duty applications requiring high shock resistance, we recommend our Juhong™ Blue Waxed & Jumbo Coils. They are heat-treated for uniform temper and edge-conditioned to prevent snapping.

Check Our Blue Waxed Steel Strapping Parameters

Steel Industry: Hot-rolled coil, cold-rolled and pickled sheets, galvanized sheets, color-coated sheets, tinplate, carbon graphite electrodes, stainless steel plates, delivered and sheared plates, seamless and petroleum steel pipes, galvanized steel pipes, steel wire ropes, steel cord, elevator guide rails, various bar and section steel products, etc.

Non-ferrous metals industry: Electrolytic copper, copper rods, aluminum ingots, aluminum coils, zinc ingots, various alloy ingots.

Glass products industry: Float glass, automotive glass, electronic glass, solar photovoltaic glass, insulating laminated glass, curtain wall glass, glass bottles, glass fibers.

Construction industry: Scaffolding

Choose the appropriate steel belt based on the weight of the goods and the usage environment.

When Cheap Strapping Becomes EXPENSIVE: Snap, Rust, and Liability

A $0.02 saving per meter sounds smart… until:

Snapped Straps: Cause $10,000 in damaged goods.

Rust Stains: Reject entire shipments of textiles or paper.

Worker Injuries: Whipping steel straps cause lacerations.

Insurance Hikes: Frequent claims = premium spikes.

Demand samples from suppliers like JUHONG Packaging. Test:

Tension strength with your tools

Corrosion resistance (spray salt mist for 24h)

Edge friction on your actual load material

Using JUHONG steel seals with their strapping ensures seamless crimping. Mismatched tools cause weak joints – the #1 failure point!

Store coils vertically in dry, covered areas. Wet strapping = pre-rusted strapping.

When you source steel strapping, you aren't just buying a metal band; you are buying a load-bearing system. You want a partner who lives and breathes strapping. Juhong Packaging Materials delivers:

Standard-Setter Precision: Because Juhong drafted the GB/T 39040 national standard for strapping seals, we manufacture our strapping to be the perfect "mate" for the joint.

Guaranteed Joint Integrity: A strap is only as strong as its joint. Pairing Juhong straps with our high-performance steel strapping seals ensures you achieve the 75% Joint Efficiency required by ASTM D3953 and international safety protocols.

ASTM/EN/GB-Certified Strapping: Globally compliant quality.

OEM/ODM: adapts seamlessly to diverse load requirements.

500+ Enterprise Clients: Trusted by giants in construction, shipping, and manufacturing.

Factory-Direct Pricing: Cut out middlemen markups.

Define Load Weight: ______ tons/kg

Environment: Indoor ☐ | Outdoor ☐ | Marine ☐

Load Material: Soft (Wood/Textile) ☐ | Hard (Metal/Stone) ☐

Required Strength: ______ N/mm² (If not sure conact JUHONG)

Coating: Galvanized ☐ | Painted ☐ | Blue Tempered ☐ | Bright ☐

Supplier Checklist: Certifications ☐ | Samples Provided ☐ | Custom Sizing ☐

Which industry do you need the steel banding for

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Choosing steel strapping isn’t rocket science – but it IS materials science. Ignore the specs, and you gamble with your goods. Master them, and you become the unshakeable hero of your supply chain. Ready to strap like a pro? Partner with experts who speak "steel" fluently. JUHONG Packaging Materials isn’t just a supplier – they’re your load’s insurance policy.

Got a monster load to secure? Get a custom strapping recommendation today → www.jsjhpackaging.com/steel-strapping

A: PET is excellent for settling loads. However, for high tensile steel strapping applications involving sharp edges, high heat, or loads that require "zero stretch" (like steel plates), steel remains the only safe option.

A: Always use a specialized steel strapping cutter and wear proper PPE. Because Juhong is the lead drafter of national safety standards, we emphasize using compatible strapping seals to prevent joint failure, which is the primary cause of whiplash accidents.

A: Using a strap that is too thin for the load weight leads to snapping, while the wrong width prevents strapping tools from sealing correctly, dropping your joint integrity below the 75% safety benchmark.

Stop overpaying traders. Source directly from Juhong Packing Materials — a factory with 27 years of experience in Steel & PET Strapping.

✅ Free Samples for quality testing.

✅ Custom Sizes (Width/Thickness) available.

✅ SGS/ASTM /EN Standard Compliance.

Don't risk your cargo safety.View Full Steel Strapping Range or Contact Us for a Free Quote Today

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America