Views: 0 Author: Sunny Yu Publish Time: 2025-12-08 Origin: Site

In the complex world of industrial logistics, secure packaging is non-negotiable. This ultimate guide, brought to you by Juhong Packaging Materials (www.jsjhpackaging.com), a trusted leader in global steel strapping and packaging solutions, goes beyond the basics to provide you with the technical expertise needed to ensure load integrity, prevent damage, and optimize your operations. Forget superficial tips—this is the definitive resource for mastering steel strapping quality, application, and procurement.

Steel strapping is the backbone of heavy-duty packaging, offering unparalleled tensile strength and durability for securing the world’s heaviest and most challenging loads, from steel coils and timber to large industrial components.

Steel strapping is essential for stabilizing loads that are prone to shifting, settling, or expanding during transport and storage. Its high break strength ensures that valuable goods remain intact, minimizing costly damage and liability issues.

• Regular Duty (RD) / Low Carbon:Tensile Strength: 830 – 880 MPa Used for light to medium loads where minimal shock is expected.

• High Tensile (HT) / High Carbon:Tensile Strength: 930 – 980 MPa The most critical type for heavy-duty applications, offering superior strength and shock resistance. This is often referenced as High Tensile Steel Strapping.

| JUHONG Steel Strapping Series | Standard | Tensile Classification | Tensile Strength(MPa) |

| Terra / Ridge | GB/T 25820-2025 | Regular Tensile | 650-750Mpa |

| Pivot / Duro | GB/T 25820-2025 | Medium Tensile | 830-930Mpa |

| Nexa | GB/T 25820-2025 | High Tensile & Low Elongation | 980Mpa |

| Ultimax | ASTM D3953 or EN 13246 | High Tensile & High Elongation | 1020Mpa |

• Stainless Steel: Used primarily in highly corrosive or high-heat environments.

While plastic (PET and PP) strapping is suitable for lighter loads, steel is irreplaceable when:

Securing extremely heavy, rigid, or sharp-edged loads.

Packaging materials that expand or contract with temperature changes (requiring high retention).

Applications where ultimate, non-yielding strength is required.

Choosing the right partner is the first step to quality. When searching for Steel Strapping Manufacturers, Steel Strapping Suppliers, or even a quick local source using Steel Strapping Near Me, prioritize companies with transparent quality control and a proven track record.

dentifying high-quality steel strapping is key to preventing catastrophic load failure. Go beyond surface-level assessment and look at the core technical specifications.

Quality is defined by precision in size and material grade.

The specific width and gauge (thickness) of the strap dictate its breaking strength and suitability for different loads. Common dimensions heavily searched for include 2 in Steel Strapping Band, 2 inch Wide Steel Strapping, 1/2 inch Steel Strapping, and 3/4 steel strapping. Ensure the supplier meets precise dimensional tolerances (e.g., 1/2”x 0.20” or 3/4”x 0.023” specifications).

The strap's finish is not just cosmetic; it is a critical factor influencing corrosion resistance, application smoothness, and is a visual indicator of material quality and treatment.

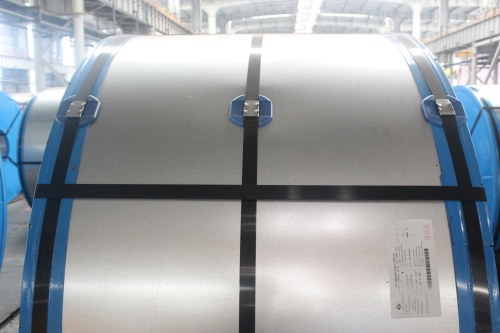

Blue Steel Strap Jumbo Coils

Black Steel Strap Jumbo Coils

zinc-coated steel strap Jumbo Coils

Blue Steel Straps (The Cost-Effective Choice): The uniform blue color is a byproduct of a precise, consistent heat treatment process, which ensures the straps possess uniform tensile strength and elongation. Crucially, blue steel is the most cost-effective option. It is typically used for general-purpose packaging or in regions/applications where there are no special requirements for rust resistance (i.e., less corrosive environments).

Painted and Waxed Straps (Enhanced Protection): These straps undergo an additional painting process, providing enhanced rust resistance. Quality assurance is key: unlike cheaper alternatives, our painted steel straps (common colors include black and green) have a paint layer thickness of at least 3–6 micrometers, effectively doubling the protection against corrosion. The waxed coating, often applied to the Painted Steel Strapping Band Black, significantly improves lubricity for smooth feeding, particularly in automated machines. These straps are often used for packaging pipes, wires, and in the floating glass industry.

Galvanized Steel Straps (Maximum Protection): These straps offer the best rust protection available. The zinc coating provides a durable and long-lasting barrier against corrosion, making Galvanized Steel Straps widely used for packaging non-ferrous metals and in environments exposed to high humidity or corrosive elements.

The true quality of steel is proven in testing:

Tensile Strength: The maximum stress the strap can withstand before breaking.

Elongation: The strap’s ability to stretch and absorb shock without failing.

Bending Resistance (Flexural Fatigue):Also known known the number of bend cycles. This measures the strap's ability to resist cracking or failure under repeated flexing or minor load movements, a key indicator of toughness and durability.

Edge Profile: Rounded or deburred edges prevent injury and enhance the strap's ability to resist lateral tearing.

The joint is the weakest point of any strapping system; therefore, the quality of the seals and fasteners is critical.

Seals, sometimes referred to as Strapping Clips or Steel Seals, are metal sleeves placed over the overlapping ends of the strap and crimped.

Lapover Seals (Overlap Seals, Closed Seals, Push Type Seals): These seals fully enclose the overlapping strap ends and are secured via mechanical deformation (friction or crimp joints).

Thread-on Seals: Used on both crimp and notch joint applications for large strap sizes (1-1/4"- 2”), they must be threaded over the overlapping strap ends before the tensioning tool is applied.

Snap-on Seals (Open Type Seals): Used primarily in notch joint applications, these seals are placed on overlapping strap ends during or after strap tensioning, helping to reduce application time in higher production environments. They may feature a grit coating on the inside to increase friction.

Open-Flange Seals: A heavy-duty snap-on variant for heavier gauge steel strapping. They feature one angled flange and are compatible with several different sealers, providing both crimp and notch joints.

Magazine Seals: These are seals designed for use in automatic or semi-automatic steel strapping machines, facilitating high-volume application.

Plastic Strapping Seals (Serrated/Dotted Seals): Use internal gripping features for friction. They are designed for manual application with PET/PP plastic strapping.

A quality Steel Strapping Seal Manufacturer or Steel Strapping Seal Supplier provides seals made of steel compatible with the strap material, ensuring the joint holds the required tension. Always look for a reliable Metal Strap Seals Factory to guarantee material consistency.

Proper application is just as vital as quality materials. The right tools and techniques ensure the load is secured to its maximum capability.

The correct equipment speeds up the process and ensures consistent tension.

Tensioners: Devices used to pull the strap tight. Key tools include the manual Tensioner for Steel Strapping and high-volume pneumatic systems.

Sealers: Used to crimp the seals (clips). Automated and pneumatic Steel Strapping Sealer or Steel Strapping Sealers are preferred for efficiency, while manual sealers are cost-effective for low-volume use.

No Steel Strapping Equipment setup is complete without a reliable Steel Strapping Cutter for safe removal and a dispenser for managing the Steel Strapping Kit and coil efficiently, minimizing waste and tangles.

The joint determines the security and integrity of the entire strap. There are two primary categories of joints:

The Seal Joint relies on a separate metal clip (Steel Seal) being crimped onto the overlapping ends of the strap. The tool (Steel Strapping Sealer) creates notches or crimps in the seal and strap, locking the layers together by friction and deformation. This method is highly reliable across various applications.

Sealless Joints are created by the strapping tool itself, without the need for a separate metal seal. This saves cost and inventory management.

Spot-weld Sealless Joints

Die-cut Sealless Joints

Die-cut Sealless Joints: The tool cuts and folds the metal in a complex pattern to create a mechanical interlock.

Spot-weld Sealless Joints: Used on some high-volume machinery, these joints use friction or heat to weld the layers of the strap together (less common in conventional steel strapping but used in specific high-end systems).

Always use corner protection to distribute stress and prevent strap cutting on load edges. Ensure even tensioning across all straps.

Always wear safety glasses. Stand clear when tensioning to avoid snap-back, and use specialized tools for cutting to prevent injury from sharp edges.

The packaging industry is constantly evolving, with a focus on both strength and sustainability.

Steel is one of the world's most recycled materials. Recycling and Material Optimization in Steel Strapping allows for the material to be reused indefinitely, making it a highly sustainable choice when managed correctly.

Continuous development focuses on automating the strapping process and enhancing material strength. The demand for High Tensile Steel Strapping continues to grow as loads become heavier and transportation demands increase.

The price of Steel Strapping For Sale depends on material grade (High Tensile is pricier), thickness, finish (galvanized costs more), and current steel market prices. Buying in bulk from a reliable supplier is key to cost efficiency.

Steel is required when strength is absolute. Plastic strapping is a good alternative when moderate tension is needed and the load requires some elasticity (e.g., lightweight palletizing).

For a detailed, in-depth comparison to determine the optimal choice for your specific application, refer to our comprehensive guide: Steel Strapping vs. Polyester Strapping: When to Use Which?

Breakage is usually caused by insufficient strap width/gauge for the load, inadequate corner protection, using low-quality seals/joints, or excessive tensioning.

Store all Steel Strapping Supplies in a dry environment to prevent premature rust, especially if they are not galvanized. Keep tools clean and lubricated to ensure reliable operation.

Juhong Packaging Materials has built its reputation by supplying products that consistently meet the highest global standards.

We apply the strict quality protocols discussed throughout this guide to every reel we produce, focusing on dimensional accuracy, consistent tensile strength, and superior finish for products like our high-demand Painted Steel Strapping Band Black.

We apply the strict quality protocols discussed throughout this guide to every reel we produce, focusing on dimensional accuracy, consistent tensile strength, and superior finish for products like our high-demand Painted Steel Strapping Band Black.

Juhong specializes in meeting precise industrial and branding needs, offering end-to-end customization:

Steel Strap Dimension Customization: We support custom steel strap width and thickness (from 1/2“ x 0.015” to 2” x 0.050”) to precisely match specific load and tooling requirements.

Color Customization: We offer customized steel strap paint colors for brand identification or simplified inventory management.

Packaging Branding: We support customized steel strap packaging (coils or cartons) and provide packaging custom logo printing services.

Seal Branding: Our Steel Seals also support custom logo embossing and customized packaging, ensuring brand consistency across your entire packaging solution.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Contact Juhong Packaging Materialstoday for top-grade steel strapping, steel seals, and strapping clips. Our experts are ready to provide technical guidance and competitive pricing.

Explore our full range of products, specifications, and certifications at www.jsjhpackaging.com.

By mastering the principles outlined in this guide—from quality identification and joint methods to tool selection—you are equipped to secure any load efficiently and safely. The choice of the right material and partner is paramount to your logistics success. For a reliable partnership and products that meet the highest global standards, Juhong Packaging Materials is ready to support your success.

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America