Views: 0 Author: Sunny Yu Publish Time: 2025-11-10 Origin: Site

When it comes to securing high-value, heavy, or bulky loads, few solutions offer the proven strength and reliability of steel strapping. Also commonly referred to as metal strapping or steel banding strap, this versatile material is the backbone of industries ranging from construction and manufacturing to shipping and warehousing. Understanding how to select and use steel strapping correctly is not just a matter of efficiency—it's a critical component of safety and cost-effectiveness. This comprehensive guide from Juhong Packing Materials will serve as your definitive resource. We will delve into the fundamental uses of steel metal strapping, provide clear guidance on choosing the right size and type (including popular choices like the 2 in steel strapping band and painted steel strapping band black), demonstrate best practices for securing pallets, and outline essential safety protocols for using steel strapping tools.

Steel strapping is also known as steel banding strap or metal strapping,A metal steel strap made from carbon steel or alloy steel that has been heat-treated, used for manual or automatic strapping, reinforcing, connecting and transporting industrial products,The term metal strapping is broader and can include straps made from other metals such as aluminum, but in most industrial settings when people say metal strapping they are almost always referring to steel strapping.At JUHONG Packing Materials we manufacture steel strapping that undergoes a proprietary deburring process, ensuring smooth, rounded edges that eliminate the risk of cuts or abrasions during handling. This feature not only enhances operator safety but also minimizes damage to packaged goods.

In the metals industry: bundling steel coils, rods, pipes, plates.

In construction: holding building materials, scaffolding parts, heavy prefabricated items.

In shipping & logistics: securing pallets, large crates, container shipments.

In specialized packaging: when high reliability is needed, e.g., heavy loads, irregular shapes.

Hot Rolled Steel Coil Packaging

Copper packaging

Steel Bar Packaging

Square tube Packaging

Steel Wire Packaging

Angle Steel Packaging

Because steel provides high strength and durability, these are typical applications where steel strapping shines.

For a detailed breakdown of which industries use steel strapping — from paper mills to metal fabrication — see our dedicated article on industries using steel strapping.

The most common application for steel strapping on pallets is to create a single, stable unit out of multiple boxes or items. This process, known as unitization, prevents individual pieces from shifting or falling off during forklift handling and truck transport.

From reinforcing steel straps for construction rebar to bundling pipes, lumber, and extruded materials, steel banding strap is the go-to choice for its ability to handle immense weight and sharp edges that would snap lesser materials.

In shipping containers and crates, steel metal strapping is often used for bracing. It can secure large items to the walls of a container or reinforce wooden crates to prevent collapse under stackable pressure.

Selecting the correct steel strapping is crucial for both safety and performance. The choice hinges on three main factors: size, strength, and coating.

Size refers to the width and thickness of the strap, directly correlating to its break strength.

Width: Common widths include 1/2 inch, 3/4 inch, 1 inch, and 2 in steel strapping band. A wider strap generally has a higher break strength.

Thickness (Gauge): This is measured in inches (e.g., .020", .023", .031"). A thicker gauge strap is stronger and more resistant to breaking under tension.

Choosing the Size: Heavier, denser loads require wider and/or thicker steel strapping. A 2 in steel strapping band is often chosen for very heavy machinery and industrial loads, while 1/2 inch or 3/4 inch may be sufficient for lighter bundles.

Steel strapping, classified by strength, can be divided into Regular Duty (or Standard) steel strapping and High Tensile (or High Strength) steel strapping.

In the marketplace for steel strapping, you’ll often see different strength categories. Many overseas buyers ask for high tensile steel strap grades, but in China a lot of manufacturers explain them according to the Chinese national standard GB/T 25820, which classifies based on minimum tensile strength (for example 630Mpa, 880Mpa, 930Mpa, 980Mpa),Because the terminology and test methods differ between standards (for example Chinese GB vs. ASTM D3953-15 or EN 13246 standards used abroad), two straps that look similar may have very different performance in elongation, break strength or finishing. That difference means the cost and pricing will also differ — even for what seems like the same high-tensile steel strapping. As a result, when you request “heavy duty steel strapping” or specify a particular elongation and strength, make sure you clarify which standard is being used, how the elongation is tested, and what guarantee the supplier gives.

At Juhong, we classify our steel strapping based on strength in accordance with the Chinese National Standard (GB/T 25820—2025).

This classification ensures that our products meet precise standards for various packing applications:

Regular Duty (RD) Steel Strapping:

Tensile Strength: 830 – 880 MPa

High Tensile (HT) Steel Strapping (also known as High Strength Steel Strapping):

Tensile Strength: 930 – 980 MPa

Series | Standard | Tensile Classification | Tensile Strength(MPa) |

Terra / Ridge | GB/T 25820-2025 | Regular Tensile | 650-750Mpa |

Pivot / Duro | GB/T 25820-2025 | Medium Tensile | 830-930Mpa |

Nexa | GB/T 25820-2025 | High Tensile & Low Elongation | 980Mpa |

Ultimax | ASTM D3953 or EN 13246 | High Tensile & High Elongation | 1020Mpa |

Tensile Strength: This value represents the maximum stress the strapping can withstand before breaking under tension.

Elongation: This figure indicates the material's ductility and its ability to stretch before failure, providing shock resistance for heavy or shifting loads.

Juhong's UltiMax™ High Tensile (HT) Series steel strapping is engineered for the most demanding heavy-duty applications, directly comparable to the performance standards set by industry leaders like Signode Magnus and USLM.

Our strapping is characterized by its High Tensile Strength combined with High Elongation, offering superior shock resistance and load integrity for critical shipments.

The UltiMax™ HT Series is manufactured to meet or exceed stringent global specifications, ensuring universal acceptance and reliability:

US Standard: Fully compliant with ASTM D3953-15 (Standard Specification for Strapping, Flat Steel and Seals).

European Standard: Fully compliant with EN 13246 (Specification for Tensional Steel Strapping).

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Bright Steel Strapping

Blue Steel Strapping

Black Painted Waxed Steel Strap

Green Painted Waxed Steel Strap

Zinc-Coated Steel Strapping

The primary surface finish classifications include:

1.Bright Steel strapping: is cold rolled , process without heat treated and metal surface (silver-gray), It offers high cost performance and reduces procurement costs.

2.Blue Tempered & Waxed:Produced by heat-treating the steel (annealing) to create a protective,At the same time, the formation of bluing film on the surface of the steel strapping and then coated a layer of water wax to form the double protection. It has excellent anti-corrosion performance to ensure long-lasting durability. Smooth and burr-free edges ensure safe handling.

3.Painted and Waxed Strapping:

This is the standard finish, where the steel is coated with paint for enhanced corrosion resistance and visibility,combines a high-quality coating with a uniform wax seal,The paint provides corrosion resistance and allows for easy identification, delivering dual defense for exceptional corrosion resistance.

Our range includes popular colors such as green and the highly sought-after painted steel strapping band black. We maintain a wide selection of color options for effective brand recognition or dedicated load segregation.

Customization: Should you have a unique color requirement or need a specific technical surface treatment, please consult directly with our technical team.

4.Galvanized (Zinc-Coated) Strapping:The steel is coated with a layer of zinc, offering superior corrosion resistance for applications exposed to moisture or extreme weather conditions. This is the premium option for long-term outdoor storage or harsh environments.

You cannot effectively or safely apply steel strapping without the right steel strapping tools. A proper toolset is a non-negotiable part of the system.

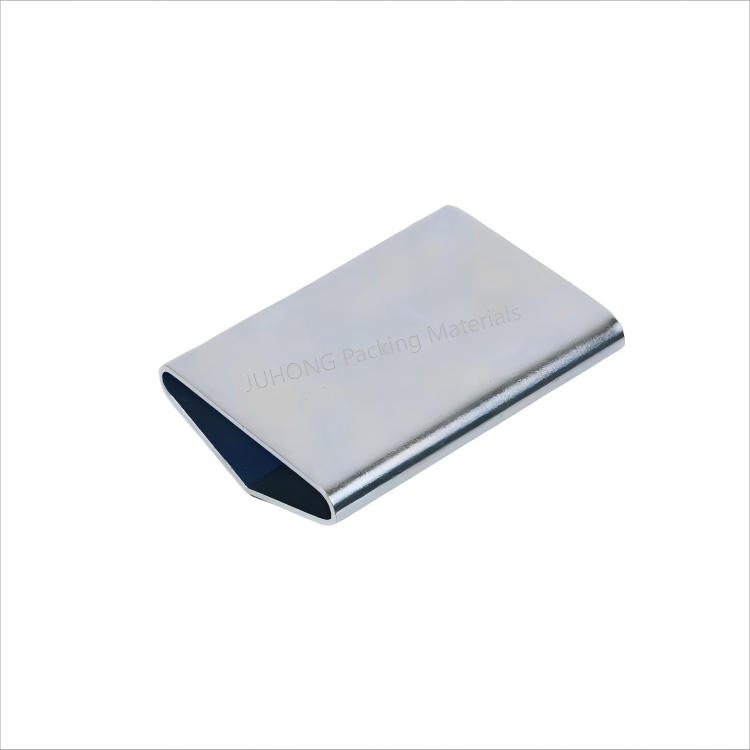

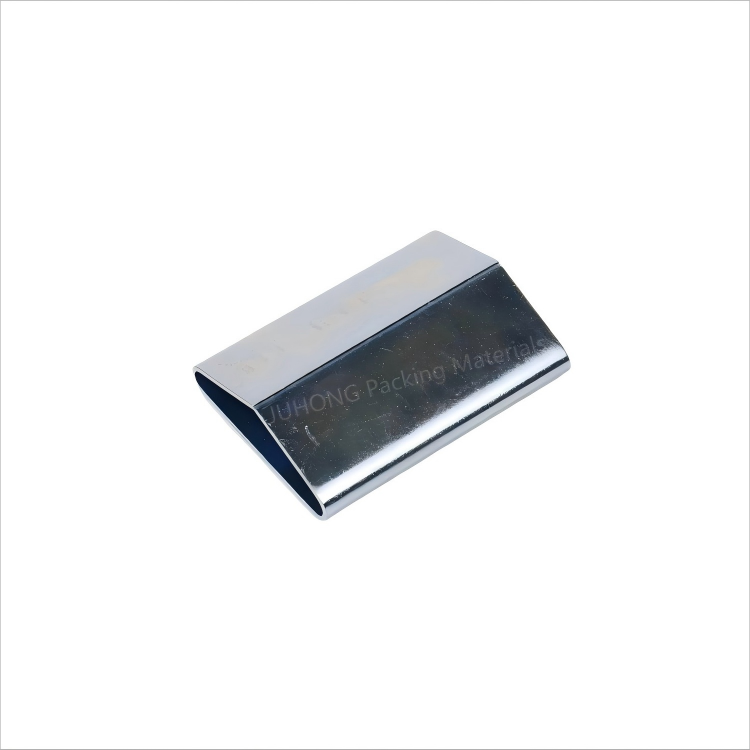

Seals for steel strapping, also known as joints or buckles, are the small metal clips that are crimped to join the ends of the strap, creating a continuous loop. The most common types are:

Push Type Seals: Also known as overlap seal、Closed seal, pressure to deform clip and steel strap into metallurgical fusion,Tamper-evident design - Destructive removal required. Closed (Push-on) Steel Strapping Sealsare the best on the market. Closed Steel Strapping Seals are used for Steel Strapping application sinvolving round or irregular shaped packages suchas coils, pipe, coiled rod, etc. Strapping is used directly from the coil, threaded through the pusher seal and formed into a "lasso" or slip loop which isthen pulled hand tight around the package.

Magazine Seals:The magazine seals are stacked together. This perm its loading partial stacks into magazines ofseal feed tools. Mostly used in combination strapping tools and power strapping machines Compatible with KOHAN /Signode/KOGYO/Titan/SMS/Generica/Sund Birsta ,for use with steel strapping.

The quality of the Steel strapping Seals directly impacts the overall integrity of the load securement. Choosing a high-quality seal is paramount, particularly for heavy-duty applications. To dive deeper into seal mechanics and the advanced features available in the market, including the patented design of our Juhong Magazine Seals, read our dedicated blog post here.https://www.jsjhpackaging.com/high-efficiency-strapping-introducing-juhong-s-magazine-seals.html

Manual tools: suitable for small batches or light applications.

Pneumatic tools: powered by air; speed up the job and give consistent tension.

Automatic/semi-automatic machines: ideal for large scale operations where speed and consistency matter.

Here is a simple step-by-step for using a tensioner:

1.Wrap the steel strapping around the load and overlap the ends.

2.Insert the end into the tensioner and pull until the strap is tight and load is secure.

3.Use a sealer or steel seal to fix the overlap joint.

4.Cut off the excess strap and remove slack.

Be careful not to overtighten—the load may get damaged or the strap may break. Make sure you use the correct tool matched to strap size and type.

Properly applying steel strapping on pallets is a systematic process. Here’s how to do it right.

1.Inspect Materials: Check the steel straps, seals for steel strapping, and tools for any damage or defects.

2.Position the Strap: Place the coil of steel strapping on a dispenser or steel strapping cart. Wrap the strap around the load and through the pallet deck boards for maximum security.

3.Thread and Engage: Insert the strap end through the steel strapping tensioner and a seal.

4.Apply Tension: Operate the tensioner to pull the strap tight. Ensure the tension is even and sufficient to compress the load without damaging it.

5.Crimp the Seal: While maintaining tension, use a sealer or the tool's built-in mechanism to crimp the seal securely.

6.Cut the Tail: Use your steel strapping cutter to cleanly remove the excess strap, leaving a short, safe tail.

Steel strapping safety is the most critical part of this guide. The high tension and strength of the material can cause severe injury if handled improperly.

Always Wear PPE: Safety glasses with side shields and heavy-duty leather or Kevlar® gloves are mandatory. Long sleeves and steel-toed boots are also highly recommended.

Never Point the Tail: When cutting, never point the loose end toward yourself or anyone else.

Maintain Your Tools: Ensure all steel strapping tools are in good working order. Dull cutters or malfunctioning tensioners are hazardous.

Handle Coils with Care: A released coil of steel metal strapping can spring open with dangerous force. Always use a dispenser cart and handle coils with control.

Dispose of Scrap Safely: Immediately collect and properly dispose of all cut ends of steel straps to prevent laceration hazards.

Mastering the use of steel strapping—from selecting the right 2 in steel strapping band for your project to applying it safely with the correct steel strapping tools—empowers you to secure your products with confidence. It is a blend of the right materials, the right techniques, and an unwavering commitment to safety.

For businesses that rely on the integrity of their shipments, partnering with a knowledgeable and reliable supplier is the final, crucial step. As leading steel strapping manufacturers and steel strapping suppliers, Juhong Packing is committed to providing not only premium-quality steel strapping and tools but also the expert guidance you need.

Ready to secure your load with confidence? Explore our full range of certified steel strapping solutions and industry-leading tools at www.jsjhpackaging.com. Our packaging specialists are here to help you select the perfect product for your application.

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America