Views: 0 Author: Sunny Yu Publish Time: 2025-11-10 Origin: Site

At JUHONG Packing Materials, with over 27 years of manufacturing experience (since 1997) and serving more than 3,000 global B2B clients (including Fortune 500 companies), we specialise in high-quality industrial packaging solutions. Our core product lines include steel strapping, PET strapping, steel seals and stretch film. We are committed to manufacturing steel strapping that meets GB, EN and ASTM standards, offering customization of colour, packaging, free samples and video factory inspections, plus global logistics and export capabilities.

This guide will answer two essential questions:

Who uses steel strapping?

How strong is steel strapping?

Steel strapping (also called steel banding) is used to secure and transport heavy, bulky, or irregular-shaped goods where strength, minimal elongation and durability are vital. Many industries turn to steel strapping because it offers high tensile strength and excellent load stability compared with plastic alternatives.

Below is a breakdown of major industries and how they use steel strapping.

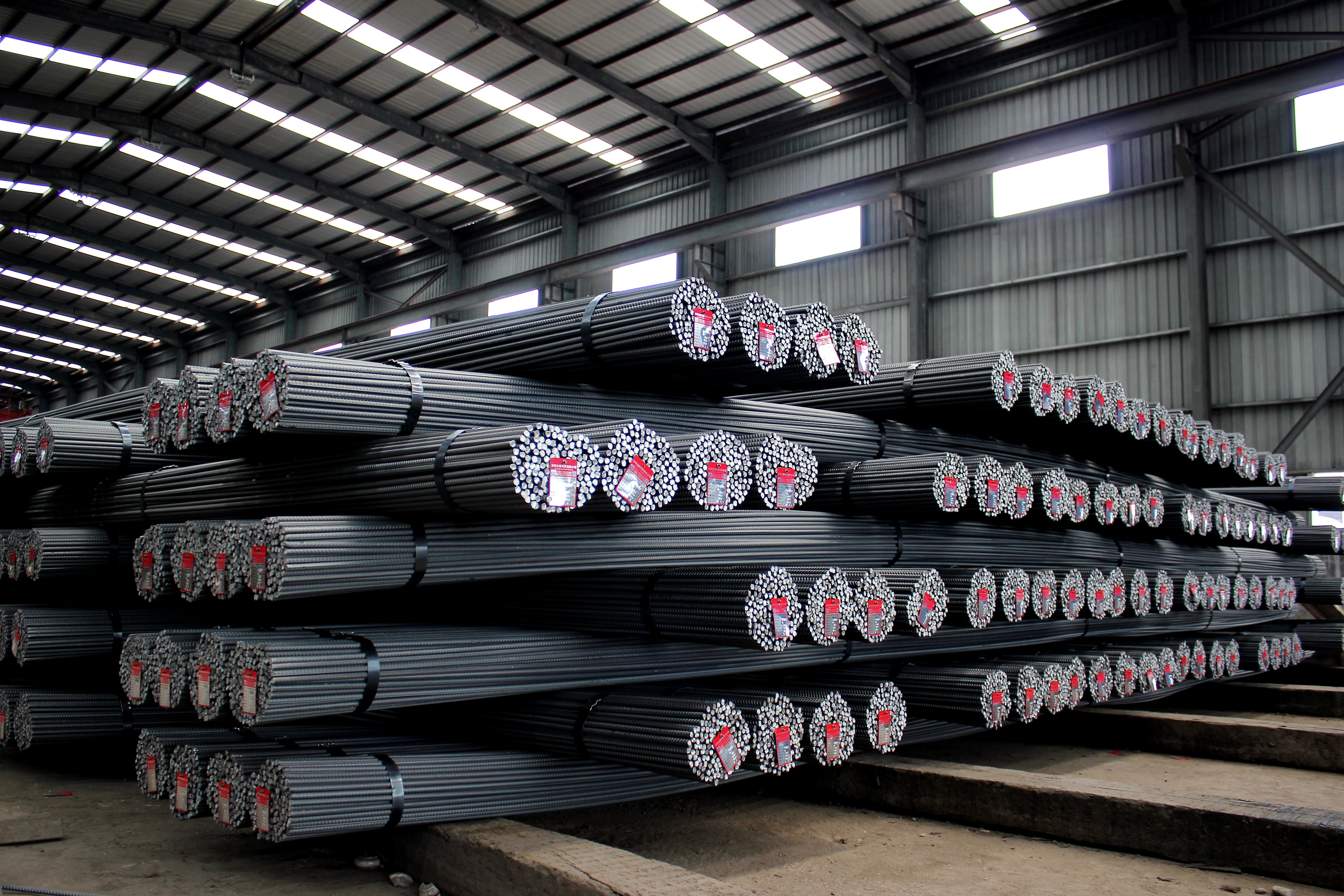

In the construction industry, steel strapping is widely used to bundle or secure materials such as steel beams, rebar, pipes, precast concrete panels, bricks, and lumber. These materials are heavy, often irregularly shaped, and subject to rough transport and outdoor conditions.

Because steel strapping can handle high tension and provides minimal stretch, it is ideal for these heavy-duty applications.

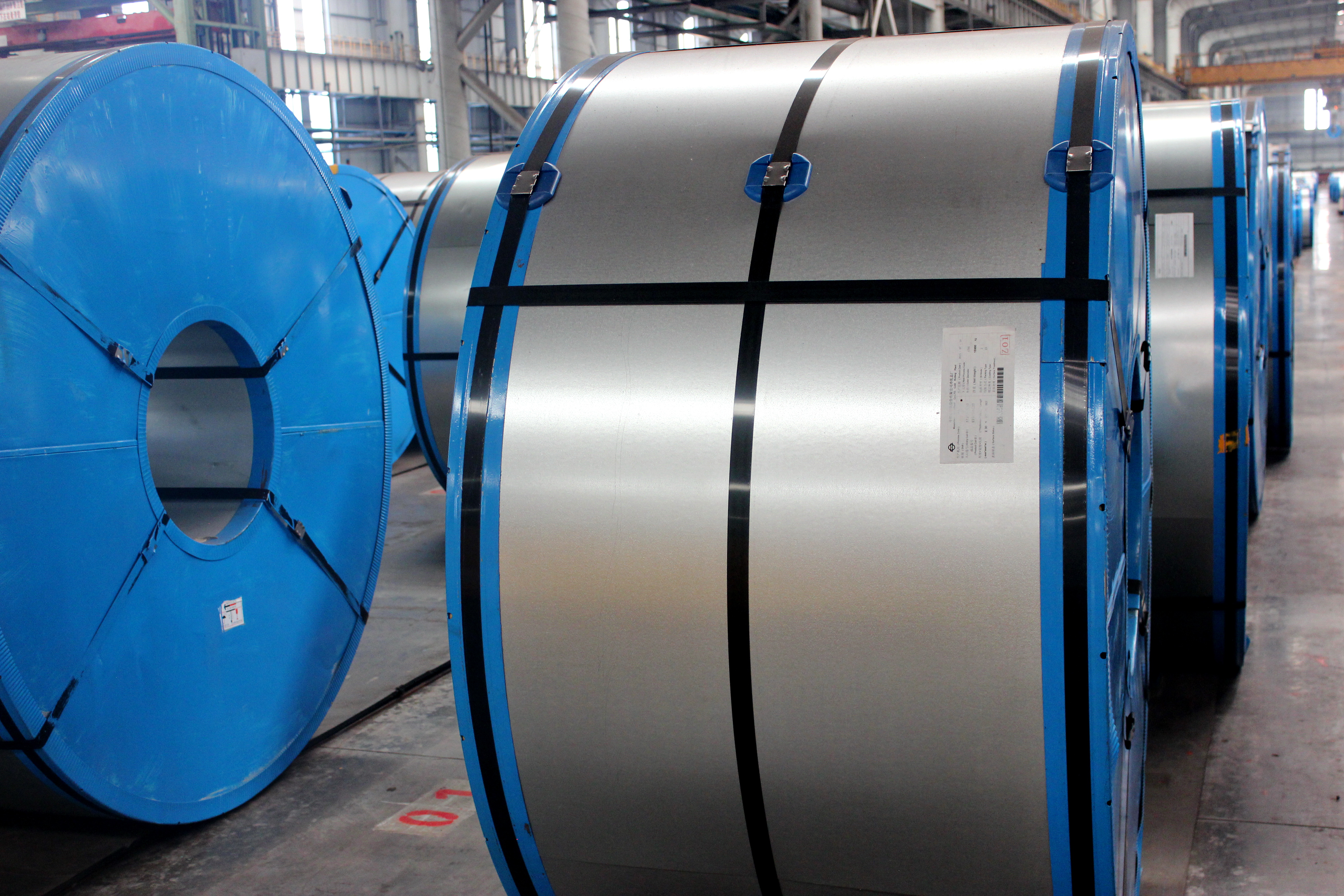

The metal industry (e.g., steel coils, plates, sheets, bars, rods) relies heavily on steel strapping. These loads are extremely heavy, often have sharp edges, and must be secured reliably for transport and storage.

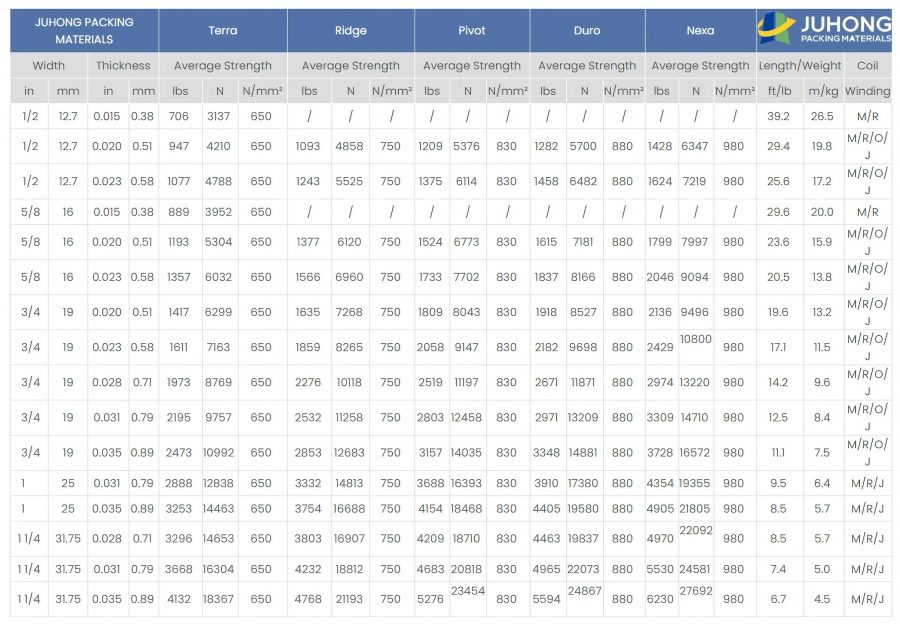

For example, regular duty and high tensile steel strapping break strengths are clearly documented by leading suppliers.

Wood products such as logs, lumber, plywood sheets and other large bundles are often strapped using steel banding. Because wood can shrink/swelling and the bundles must remain stable, steel offers superior rigidity and minimal elongation compared to plastic strapping.

Heavy paper rolls, corrugated board bundles, carton stock and other bulk paper packaging products use steel strapping to maintain bundle integrity and prevent shifting. The smooth finish of steel strapping helps reduce damage to surfaces.

Large panes of glass, stacked glass products and other fragile yet heavy items require reliable strapping to avoid breakage during transit. Steel strapping provides the necessary strength and stability to secure these loads safely.

Agriculture: Steel strapping is used for bundling bales of hay or large agricultural goods, as well as securing machinery for transport.

Recycling: In the recycling industry, steel strapping is used to compress and bind scrap metal, paper or plastics into dense, transport-ready bales.

These applications require high strength and durability, making steel strapping a logical choice.

In shipping and export logistics, steel strapping is used to secure pallets, heavy industrial machinery and cargo for long-distance transport (sea, rail, truck). Because steel strapping has very low elongation under load and performs well in harsh outdoor and transport environments, it is frequently used for heavy loads and export container securing.

| Industry | Typical Use Cases |

|---|---|

| Construction | Steel beams, pipes, rebar, concrete panels |

| Metal / Steel | Coils, plates, sheets, bars, rods |

| Timber / Lumber | Logs, lumber bundles, plywood, outdoor stacks |

| Paper / Packaging | Heavy paper rolls, board bundles, carton stock |

| Glass | Large glass panes, stacked glass products |

| Agriculture | Hay bales, bundling large farm goods |

| Recycling | Scrap metal bales, compressed paper/plastics |

| Logistics / Export | Heavy machinery, container securing, pallet loads |

In short: Who uses steel strapping? The answer is: virtually any heavy-duty industry where securing large or heavy bundles is required.

Understanding how strong steel strapping is — its tensile strength, break strength, yield, elongation and suitable specifications — is key for selecting the correct product and evaluating potential steel strapping suppliers.

When discussing steel strapping strength, several metrics are relevant:

Tensile strength: The maximum stress the strapping material can withstand while being stretched before breaking.

Break strength (or average break): The load at which the strap will fail under tension.

Yield strength: The stress at which permanent deformation begins.

Elongation: The degree of stretching before break — for steel strapping this is normally very low .

Having high tensile/break strength and low elongation means the strapping holds loads more rigidly.

When you strap a heavy load (e.g., a steel coil, timber bundle or concrete product), you need the strap break strength to exceed the expected tension/force applied during transport + a safety margin.

Low elongation means that under load the strap won’t stretch significantly, which is important for maintaining tightness and preventing shifting of the bundle.

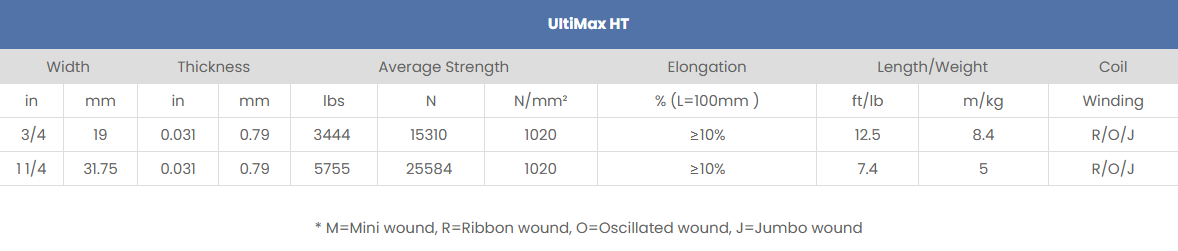

Choosing between Regular Duty vs High Tensile: for lighter loads you might use RD, but for heavy, long-haul, high-shock applications you should go with High Tensile.

As a supplier or buyer in the steel strapping market looking for reliable steel strapping suppliers, consider the following:

Load weight: heavier loads call for higher break strength.

Transport environment: long distance, multiple handling, vibration, shock, outdoor conditions — lean toward high tensile, corrosion-resistant finishes (e.g., zinc coated steel strapping,stainless steel strip).

Material edges/sharpness: if you’re bundling pipes or rods with sharp edges, the strap must be strong enough and the surface finish smooth to avoid edge-cutting or strap failure.

Finish and environment: If exposure to moisture, salt, outdoor storage is expected, then zinc-coated or epoxy/zinc finishes matter. One supplier differentiates finishes like Unpainted & Waxed, Painted & Waxed, Zinc/Epoxy Coated (ZE), Pro-Zinc Silver (PZ) for superior corrosion resistance.

Tool compatibility & seals: The joining method (seals, welds, friction welds) can affect actual strap strength in practice. Careful selection of strap & tool is essential.

The term AAR refers to the Association of American Railroads, which publishes standards and approvals for components used in rail freight

Products labeled “AAR Approved steel strapping” or “AAR Certified Strapping” mean the strap meets the rugged demands of rail-car load securement and heavy industrial packaging.

When your cargo involves rail transport, export containers or extremely heavy loads, using AAR-approved strapping offers added assurance:

It suggests the strap has passed rigorous testing and is suitable for load securement in the rail industry.

It can open you to markets and applications where “rail-qualified” materials are required.

At JUHONG, we are proud to mention that our high-tensile steel strapping is being engineered to meet AAR-approval levels. We are currently in the process of applying for full AAR Certification, which will allow us to offer AAR Approved steel strapping and AAR Certified Strapping to customers requiring rail-tier packaging.

What this means for you:

When the certification is granted, our coils will carry the “AAR” mark, manufacturer name and approval number, enabling you to confidently specify our product for rail securement.

The product will be engineered to the stringent break strength, elongation and edge-condition requirements that AAR mandates—making it suitable for the heaviest and most demanding packaging tasks.

With AAR-level certification, JUHONG positions itself not just as a quality steel strapping supplier, but a supplier capable of servicing premium segments in the steel strapping market.

Since 1997, JUHONG Packing Materials has specialized in high-quality packaging materials — steel strapping, PET strap, stretch film — boasting decades of production knowledge, global logistics and B2B service to thousands of customers.

Standard duty and high-tensile steel strapping.

Surface finishes: painted & waxed, blue-painted, black-painted & waxed, galvanized or zinc coated.

Custom widths, thicknesses, colors, packaging and branding (ideal for customers wanting private-label or bespoke specifications).

Free sample service, video factory inspection and sustained global logistics capability.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Our steel strapping meets international standards (GB, EN, ASTM) and our quality control ensures consistent width/grade/thickness. We provide high-strength steel strapping options that support heavy-duty applications across industries.

We serve customers worldwide: paper industry, steel & non-ferrous metals, glass, construction, logistics, packaging. We understand the demands of industries requiring high-strength, reliable steel strapping. We are equipped to handle global shipping and support multilingual markets (including Spanish, Russian, etc.).Contact us to get free sample!

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America