Views: 0 Author: Sunny Yu Publish Time: 2025-11-21 Origin: Site

As the logistics and export sectors in South America continue to expand—driven by the intense agricultural demands in Argentina and the massive mining operations in Peru—the choice of packaging materials has evolved from a simple commodity purchase to a strategic supply chain decision.the demand for stretch film (also known as pallet wrap or stretch wrap) has skyrocketed. In countries like Peru, Chile, and Uruguay, industrial buyers are increasingly prioritizing high-performance "Stretch Film" over generic wrapping products to ensure stability during long-haul maritime and mountain transit.

This guide highlights the top 7 stretch film manufacturers and global suppliers that are particularly relevant to the South American market. We evaluate their capabilities, business models, and strengths. We also introduce Juhong Packing Materials, a factory‑direct stretch film manufacturer offering highly competitive, high-elongation film suited for B2B logistics and industrial buyers.

The specific requirements of the South American market are shaped by its unique geography and the ongoing modernization of its industrial hubs. Understanding these drivers is essential for any procurement manager looking to optimize their packaging costs.

In the high-altitude and rugged terrains of the Andes, cargo stability is a primary concern. Logistics managers in Peru and Chile are moving away from low-grade wraps in favor of advanced PE Stretch Film that can withstand significant temperature fluctuations and mechanical stress. This ensures that heavy industrial exports remain secure from the mine or factory all the way to the international port.

With the rapid automation of distribution centers in Mexico and Chile, there is a clear shift from manual hand-wrapping to high-speed machine applications. This transition reflects a desire for "Packaging Precision"—using machine stretch film with high pre-stretch ratios to reduce plastic waste per pallet while ensuring consistent load containment that human operators cannot match.

In the complex road networks of South America, the security of goods in transit is a top priority. This has led to the widespread adoption of Black Stretch Film. Beyond protecting sensitive products from UV damage during outdoor storage, black film acts as a "visual shield," concealing high-value cargo from theft during long-distance trucking and multi-stage transshipment.

Professional buyers are increasingly looking to establish direct relationships with manufacturers rather than relying on general trading platforms or local middlemen. This direct-sourcing model allows for deep customization—such as specific micron thicknesses or specialized additives—that is necessary to meet the rigorous demands of the South American climate and infrastructure.

While local suppliers can offer advantages like shorter lead times, importers often face limited film variety (such as gauge or color), inconsistent quality, or higher per-unit costs for high-volume orders. For many B2B buyers, a mix of local and global stretch film suppliers provides the best balance between cost, quality, and reliability.

Key properties of stretch film include:

Elongation / Stretch: High-performance films can stretch 500% or more.

Gauge / Thickness: Determines strength and protection.

Puncture Resistance: Critical for heavy or irregular loads.

Cling / Adhesion: Ensures layers hold together.

Also, specialty films (colored, black, UV-stabilized) are increasingly in demand for security, load identification, and outdoor storage.

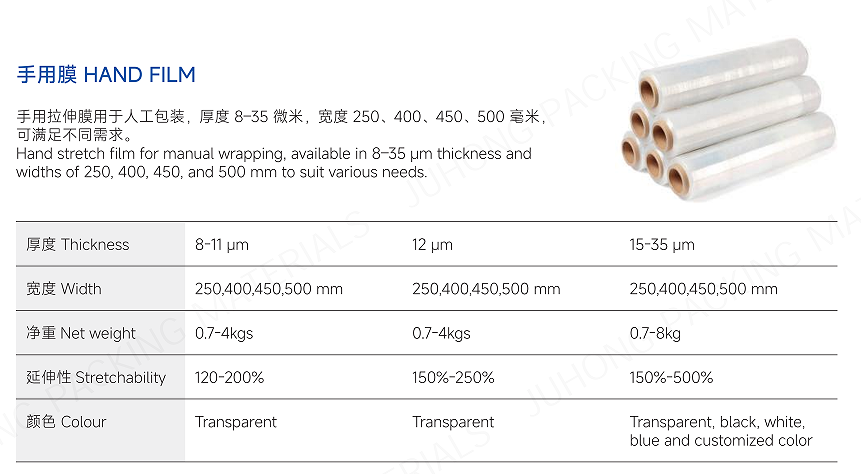

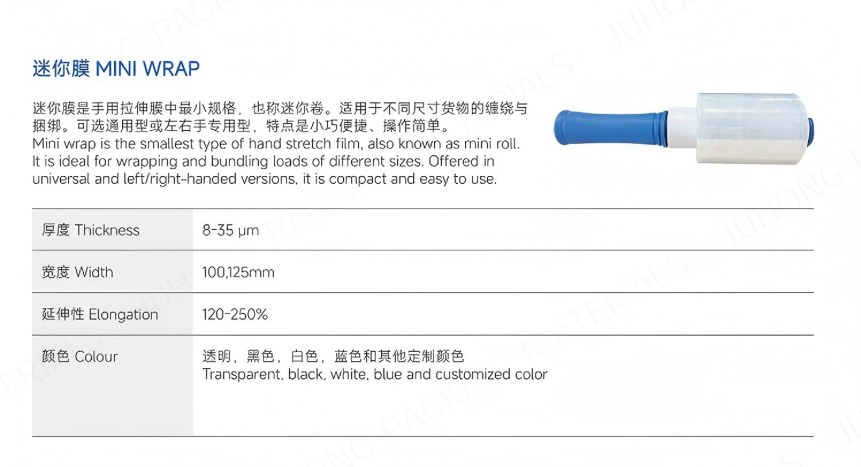

Ability to produce both machine stretch film and hand stretch film

Large capacity for jumbo-roll stretch film, ideal for high-volume users

Multiple production lines to ensure supply stability

Variety of gauges (thickness) and widths

Options for color, core size, and recycled-content film

Specialty products: pre-stretched film, UV-stabilized film, etc.

Compare wholesale stretch film offers vs local pricing

Evaluate landed cost (including freight and duties)

Negotiate long-term contracts to lock in volume discounts

Does the manufacturer have export experience to South America?

Are there warehouses or partners in the region?

What are lead times for repeat orders?

Does the company provide testing data for elongation, strength, and puncture?

Are there quality certifications (ISO, MSDS, Rohs,Reach,etc.)?

How sustainable is the production (energy usage, recycling, renewable power)?

Here are the top 7 stretch film producers that are particularly relevant for South America — combining global reach, technical strength, and product innovation.

Website: amcor.com

Type: Global Packaging & Flexible Films

Established: 1860

Intro:Amcor is a global packaging leader. In April 2025, it completed its all-stock acquisition of Berry Global, bringing Berry’s industrial stretch film capabilities (machine and hand wrap) into its flexible packaging division.

The merger strengthens Amcor’s ability to deliver high-performance stretch film for large B2B customers in South America, offering advanced logistics, material science, and sustainability innovation.

Website: www.sigmastretchtools.com

Type:Stretch Film Manufacturer & Flexible Packaging

Established:1980s (stretch film division)

Intro:Sigma Stretch Film is part of Sigma Plastics Group and specializes in a wide spectrum of LLDPE stretch films — from blown to cast, machine to hand. Their “Rite‑Gauging®” tool helps customers optimize film usage to reduce waste and cost, making them an attractive supplier for high-volume logistics and industrial operations.

Website: jsjhpackaging.com

Type: Factory‑Direct Stretch Film Manufacturer

Established: 1997

Intro: Juhong Packing Materials is a factory-direct stretch film manufacturer offering high-elongation machine stretch film (300–500%), hand stretch film, jumbo rolls, and customizable film options. Their quality control includes rigorous testing (elongation, puncture, tensile strength), and they are certified for RoHS, REACH, and MSDS

Their direct model helps South American customers access wholesale stretch film at competitive prices with stable, long-term supply.

Website: itape.com

Type: Packaging Products & Systems

Established: 1981

Intro: IPG is a North American packaging giant that produces tapes, protective packaging, and stretch wrap. Their industrial stretch film business includes both machine and hand film, serving warehousing, 3PL, and manufacturing sectors. IPG’s wide reach and experience make them a reliable partner for importers in South America.

Website: manupackaging.com

Type: Stretch Film Manufacturer

Established: 1969

Intro: Manupackaging (originally Manuli Stretch) has decades of experience producing LLDPE pallet wrap, stretch hoods, and industrial films. With production plants in Europe (Germany) and South America (Brazil, Argentina), they combine technical expertise with broad geographic reach. Their products are well-suited for both local and export logistics.

Website: paragonfilms.com

Type: High‑Performance Cast Stretch Film Manufacturer

Established: 1988

Intro: U.S.-based Paragon Films specializes in ultra-high-performance cast stretch film. Their LLDPE films stretch further, hold better, and use less material — a “thinner, stronger, greener” approach. This makes them ideal for industrial users who want superior load hold and efficient material use.

Website: bomarkpak.hr

Type: Cast Stretch Film Manufacturer

Established: 2005

Intro:Bomark Pak, based in Croatia, is one of Europe’s leading cast stretch film producers. Their 20-hectare facility is highly advanced and includes a 15 MW solar power installation, supporting their “green transition” in stretch film production.

Bomark Pak’s product range includes more than 200 film variants and they operate an in-house R&D laboratory for stretch film testing.

Their scale and sustainable production make them a strong partner for environmentally conscious importers in South America.

In the professional logistics sector, Cast Stretch Film is becoming the preferred choice due to its uniform thickness and quiet unwind properties. For large-scale sortation centers, this reduces noise pollution and improves the overall speed of the packing line.

Given the long lead times often associated with South American shipping routes, buyers are prioritizing suppliers who can guarantee raw material quality. Sourcing directly from a manufacturer ensures that the LLDPE resins used are virgin grade, preventing the film from becoming brittle during long-term storage or transit.

Juhong’s model removes many middlemen, allowing you to negotiate for factory-direct machine stretch film, hand stretch film, jumbo rolls, and custom film — all at wholesale stretch film pricing. This model can reduce your total cost per pallet.

Their film is engineered for very high elongation (up to 500%), which means more stretch per meter and better load tightness. Their quality control process ensures every batch meets high standards.

Juhong is well-experienced in international exporting. For South American customers, they can provide consistency, technical support, and flexible order sizes to match your needs.

Although based in China, Juhong is committed to high-quality production with minimal waste. Their LLDPE films are recyclable, and their production processes are designed for efficiency.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

Juhong Stretch Film SDS Certificate.pdf

Juhong Stretch Film SDS Certificate.pdf

Juhong Stretch Film RoHs Certificate.pdf

Juhong Stretch Film RoHs Certificate.pdf

Juhong Stretch Film REACH Certificate.pdf

Juhong Stretch Film REACH Certificate.pdf

Bomark Pak is leading the way among stretch film producers with its 15 MW solar power plant, drastically reducing its energy footprint and aligning with global sustainability trends.

Modern stretch film manufacturers are pushing performance with thinner, stronger films that stretch more, hold tighter, and reduce material use. Paragon Films and Juhong are prime examples.

Customers increasingly demand films with recycled content, UV stability, and color-coded options. Leading manufacturers now offer these variants to meet both performance and ESG (environmental, social, governance) goals.

Combine major global suppliers (like Amcor or Sigma) with factory-direct partners (like Juhong) to balance cost, performance, and supply security.

Ask for film samples from each potential supplier. Test for elongation, puncture resistance, and load retention relevant to your pallet loads.

Secure favorable pricing and supply by agreeing to multi-year contracts and volume commitments. This reduces risk and ensures consistency.

Partner with eco-conscious manufacturers (e.g., Juhong) to support your company’s ESG objectives. Ask for certifications or sustainability reports.

Plan for lead times, import cycles, and local stocking to avoid supply disruptions. Use local logistics partners or negotiate with suppliers who understand South American routes.

The South American market demands high-performance packaging solutions that can withstand long-distance logistics. By focusing on the right stretch film manufacturers and staying ahead of industrial needs—from automated machine films to specialized security wraps—your business can ensure cargo safety while optimizing costs.

Contact Juhong today to request samples of our high-performance PE Stretch Film and see why we are the preferred factory-direct partner for the South American industrial sector.

The Ultimate Guide To Sourcing Stretch Film in Saudi Arabia: 2026 Strategic Review

Top 12 Stretch Film Manufacturers in the USA (2026 Comparison)

Top 10 Stretch Film Manufacturers in Saudi Arabia (2025) + Market Trends & Buyer Guide

Who Uses Stretch Film? A Complete Industry Guide by Juhog Packing Materials

Why Stretch Film Is The Ultimate Solution for Testliner Paper Packaging?

TOP 6 Stretch Film Manufacturers You Should Know in Janpan in 2025