In over 28 years of navigating the industrial packaging landscape at Juhong, we’ve consulted for thousands of facility managers from the construction sites of Saudi Arabia to the manufacturing hubs of Vietnam and the USA. We’ve heard the same concerns repeatedly: "Will plastic really hold my 2-ton load?" and "Is the switch actually worth the investment?"

If you are currently ordering painted steel strapping band black or high tensile steel strapping, you are likely overlooking a massive leak in your operational budget. This guide is based on 28 years of field-testing. It provides a data-backed ROI analysis for procurement heads looking to navigate the volatile material costs of 2026.

The Financial Blueprint: Why the "Price Per Ton" of Steel is a Procurement Trap

Many procurement departments make the mistake of comparing steel metal strapping to PET (Polyester) strapping based on weight. In our two decades of experience, we call this the "Price Per Ton Trap."

The 4:1 Yield Advantage: Getting More "Feet" for Your Dollar

Steel is incredibly dense. PET is a high-strength polymer. When you buy a ton of steel, you get a relatively short length of material.

The Math: For the same weight, PET strapping typically provides 4 times the linear footage of steel.

When looking for steel strapping for sale, your metric should be cost per foot, not cost per pound. Switching to PET typically results in a 30% to 50% immediate reduction in raw material expenditure.

Eliminating Hidden Consumables: The End of Metal Seals

Standard steel strapping tools often require metal seals (clips).

The Innovation: Most modern PET transitions utilize Pneumatic Plastic Strapping Tools that use friction-heat welding.

The Saving: By eliminating seals, a high-volume facility can save tens of thousands of dollars annually. We’ve seen plants pay for their entire fleet of new tools within six months just from seal savings.

Technical Integrity: Why PET Often Outperforms "Heavy Metal”

A common myth we debunk is that "plastic is weak." After 28 years of testing, we know that load retention is more important than absolute break strength.

Elastic Memory: The "Shock Absorber" Effect

The Failure of Steel: Steel is rigid. If a load of lumber or bricks settles during a bumpy transit to Jeddah or Los Angeles, the steel strap becomes loose. A loose strap is a safety hazard.

The PET Advantage: PET has "memory." It stretches under tension and contracts as the load settles. This constant tension is why AAR Approved PET Strapping is now the gold standard for heavy-duty rail and sea freight.

The Storage Nightmare: Rusting in the Shadows

One of the most frustrating issues for warehouse managers is storage degradation.

The Vulnerability: Even if you buy high-quality painted steel strapping or galvanized steel straps, time in a typical warehouse is your enemy.

The Veteran's Observation: In dark, damp environments—common in humid climates like Vietnam—moisture settles between the coils of steel. If stored for an extended period, the steel begins to rust from the inside out before it even touches a pallet.

The PET Solution: PET is 100% rust-proof. It doesn't care how long it sits in a humid warehouse or a dark corner. It remains factory-fresh, ensuring it won't stain your Expensive Stone, Timber, or Paper Products.

Industry-Specific Applications: Where PET Wins

Based on our Industry Expertise, here is how the switch to PET impacts specific sectors:

![Heavy-Duty Green PET Strapping for Outdoor Brick Palletization Heavy-Duty Green PET Strapping for Outdoor Brick Palletization]()

1. Construction and Building Materials (Bricks, Tiles, Stone)

In the construction sector, especially in high-growth markets like Saudi Arabia, the primary challenge is impact resistance.

Strategy: High-tensile PET banding replaces 3/4 x .023 steel strapping. It absorbs the shocks of forklift handling much better than brittle steel.

2.Timber and Wood Processing

![AAR Certified PET Strapping for Secure Lumber and Timber Bundling AAR Certified PET Strapping for Secure Lumber and Timber Bundling]()

In our two decades of serving the lumber industry, we have always emphasized one thing: Wood is a "living" material. It breathes, meaning it constantly expands and contracts depending on the ambient humidity and temperature.

The Problem with Steel: Steel strapping is completely rigid. When timber bundles are stored in a dry environment or a high-heat region like Saudi Arabia, the wood shrinks as it loses moisture. Because steel cannot contract, the straps quickly become loose, leading to dangerous "pallet slumping" or bundle disintegration during transport.

The PET Advantage: This is where PET's Elastic Memory becomes a lifesaver. PET strapping has the unique ability to "breathe" with the wood. As the timber shrinks, the strap maintains its tension, keeping the bundle tight and secure. Conversely, if the wood expands in humid climates like Vietnam, PET has enough elongation to absorb that expansion without snapping.

Surface Protection: Unlike steel banding straps, which often bite into the corners of softwoods and leave permanent damage or rust stains, PET is non-abrasive. It secures the load without deforming the product, ensuring your high-grade timber arrives in premium condition.

3.Metal and Aluminum Ingots: High-Tension Security Without the Corrosion

![Cold rolled steel coil packing 1(1)(1)(1) Cold rolled steel coil packing 1(1)(1)(1)]()

![high-tensile-pet-strapping-aluminum-ingots-packaging Heavy-duty PET strapping applied on aluminum ingot bundles in a smelting plant, replacing 1 1/4 inch steel strapping]()

For decades, the metals industry relied exclusively on 1 1/4 inch steel strapping to secure heavy aluminum ingots and steel coils. However, our 28 years of field experience show a massive shift toward High-Tensile PET Strapping in this sector, driven by two non-negotiable factors: Cost and Contamination.

Preventing Metal-on-Metal Oxidation: One of the biggest headaches for aluminum ingot exporters is "contact rust." When standard steel metal strapping is used, any moisture—even from high-humidity storage—causes the steel to rust, which then leaches onto the aluminum. This stains the ingots and can lead to quality rejections from high-end automotive or aerospace clients. PET is inert; it will never rust, ensuring your metal remains in "mill-finish" condition regardless of the shipping duration.

Superior Shock Absorption for Heavy Loads: Heavy metal loads are subject to intense G-forces during transit. While high tensile steel strapping is strong, it is also brittle; it can snap under sudden impact. PET has the elongation required to absorb these shocks without failing, keeping the bundle intact even during rough handling.

Economic Impact on High-Volume Lines: Switching from 1 1/4 inch x .031 steel to a heavy-gauge PET alternative drastically reduces the cost per foot. In high-output smelting and casting facilities, the savings on material alone can reach hundreds of thousands of dollars annually, without sacrificing a single pound of break strength.

Safety: A More Forgiving Working Environment

In the past, steel was notorious for being dangerous. Today, Juhong steel strapping is deburred, meaning the edges are smooth and won't cut your hands during normal handling. However, the "Whiplash Effect" is still a factor of physics.

Managing Stored Energy

When any strap is under thousands of pounds of tension, it stores energy.

The Snap-Back: When steel is cut, that energy is released instantly. Because steel is heavy and rigid, the "snap-back" is violent.

The PET Difference: PET has lower kinetic energy. It doesn't "whip" with the same lethal force as steel metal strapping. This makes the warehouse floor a less stressful environment for your operators, especially during high-speed decanting of pallets.

Operator Fatigue

Lifting a jumbo coil of painted steel strapping is a back-straining job. PET is significantly lighter, making it easier to load into dispensers and pull around large loads, reducing long-term repetitive strain for your team.

Specification Conversion: Replacing Your Steel Sizes

| Current Steel Specification | Recommended PET Strapping Alternative | Application Level |

| 1/2 x .020 Steel Strapping | 12.7mm x 0.8mm PET strapping | Light Bundling |

| 5/8 Steel Strapping | 16mm x 0.9mm PET strapping | General Palletizing |

| 3/4 x .023 Steel Strapping | 19mm x 1.0mm Heavy-Duty PET strapping | Heavy Construction / Metal |

| 2 inch Steel Strapping Band | Specialized 25mm+PET strapping | Extreme Load Bundling |

![Juhong_polyester_strapping_Parameter]()

2026 Global Trends: Sustainability and the "Green" Mandate

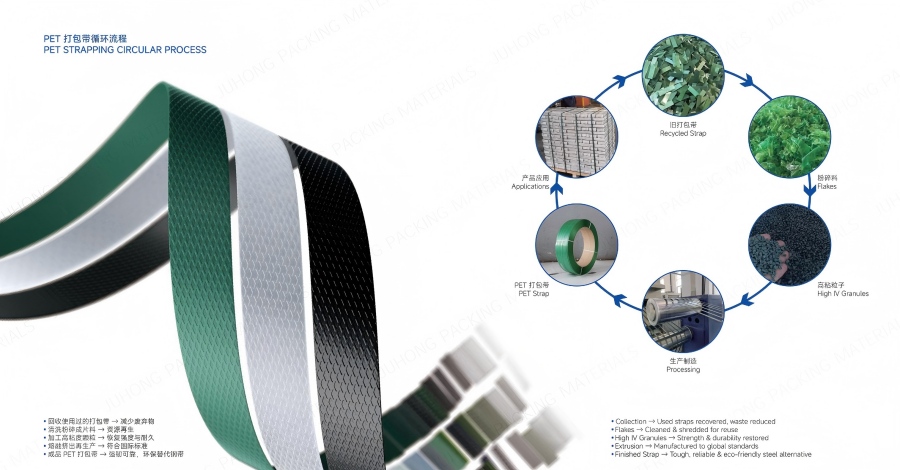

![PET strap recycling process flowchart 1 PET strap recycling process flowchart 1]()

As we look toward 2026, Sustainability is no longer optional.

The Problem with Steel: Scrap steel is hard to handle, dangerous to recycle, and has a massive carbon footprint during production.

The PET Advantage: PET is 100% recyclable. Many of our partners in Europe and the USA now mandate PET because it aligns with their ESG (Environmental, Social, and Governance) goals.

![]() juhong packing Polyester strapping Brochure.pdf

juhong packing Polyester strapping Brochure.pdf

![]() Juhong Packing Materials AAR PET Strap Certificate.pdf

Juhong Packing Materials AAR PET Strap Certificate.pdf

![]() SDS-PET Strapping-XMIN2504001091PC14-1_EN.pdf

SDS-PET Strapping-XMIN2504001091PC14-1_EN.pdf

![]() REACH_SVHC_PET Strapping_XMIN2504001091PC05_EN.pdf

REACH_SVHC_PET Strapping_XMIN2504001091PC05_EN.pdf

![]() RoHs_PET Strapping_XMIN2504001091PC04_EN.pdf

RoHs_PET Strapping_XMIN2504001091PC04_EN.pdf

FAQ: Expert Answers to Common Strapping Transition Questions

Q1: Can PET strapping really match the break strength of 3/4 inch high-tensile steel?

A: Yes, but with a technical distinction. While 3/4 x .023 steel strapping has a higher absolute breaking point, high-density PET offers sufficient "System Strength" for 90% of heavy-duty applications. In our 20 years of testing, we’ve found that PET’s ability to absorb shock (elongation) often prevents snaps that occur with brittle steel during sudden forklift movements. For extreme loads, we recommend moving to a thicker gauge 19mm x 1.27mm PET to ensure a 1:1 safety ratio.

Q2: What is the true cost-per-foot difference between Steel and PET?

A: On average, PET is 30% to 50% cheaper per foot than steel. Buyers often get confused by "price per ton." Because PET is roughly four times lighter than steel, one ton of PET gives you approximately 4,000 meters of strap, whereas one ton of steel might only give you 1,000 meters. When you factor in the elimination of metal seals (clips) by using a , the total operational saving is substantial.

Q3: Does PET strapping lose tension if stored in hot climates like Saudi Arabia?

A: This is a common concern on industry forums. Unlike cheaper polypropylene (PP) which sags in heat, High-Performance PET is designed to maintain its "Elastic Memory" even in temperatures up to 70°C. In regions like Saudi Arabia, PET actually outperforms steel because it won't expand and become loose as the metal heats up in the sun. It stays "snug" around the load, ensuring stability from the desert warehouse to the port.

Q4: How do I prevent rust when storing strapping for long periods in humid regions like Vietnam?

A: If you are using painted steel strapping band black, long-term storage in damp, dark environments is almost guaranteed to cause "hidden rust" between the coils. The only 100% effective solution is switching to PET. Since PET is a polymer, it is chemically incapable of rusting. You can store it in high-humidity areas for years without worrying about it snapping due to corrosion or staining your expensive timber or paper exports.

Q5: Is it hard for my warehouse team to learn how to use PET tools compared to steel?

A: Actually, most teams prefer the switch. Modern deburred steel straps have improved safety, but they are still heavy. PET is much lighter, reducing operator fatigue. Transitioning from an A333 manual tool to a usually takes less than 30 minutes of training. The process is faster, quieter, and eliminates the physical strain of hauling heavy steel coils around the loading dock.

Conclusion: Start Your ROI Journey with Juhong

The switch from steel metal strapping to PET is one of the easiest ways to improve your bottom line in 2026. You save on material, eliminate seals, improve safety, and protect your cargo.

With over two decades of experience, we don’t just provide strapping; we provide the expertise to ensure your transition is seamless. Whether you are in the USA, Vietnam, or Saudi Arabia, we have the local market knowledge to help you succeed.

Would you like a custom ROI calculation? Contact our team today, and let’s look at your current usage of steel banding straps to find your perfect PET match.

简体中文

简体中文