Views: 0 Author: Sunny Yu Publish Time: 2025-11-17 Origin: Site

Steel strapping is a cornerstone of logistics, packaging, and storage across numerous industries in Australia. From mining to construction, steel strapping plays an essential role in securing heavy loads, ensuring that equipment, materials, and products arrive safely at their destination. As one of the most reliable, durable, and versatile packaging solutions available, steel strapping has become indispensable for Australian industries such as mining, timber, and metal fabrication.

The Australian logistics sector, responsible for moving a wide variety of goods, relies heavily on steel strapping. Industries like mining use it to secure raw materials and equipment, while construction companies need it to ensure materials stay in place during transportation. The timber and metal fabrication industries also rely on steel strapping for bundling and securing products. These sectors require packaging solutions that are robust, secure, and resistant to the elements, making steel strapping the go-to choice.

While one-time purchases might seem sufficient for small-scale operations, long-term partnerships with reliable steel strapping suppliers are essential for businesses looking to scale. Wholesale steel strapping suppliers in Australia offer cost-effective solutions by allowing bulk buying options and providing ongoing support. Long-term supplier relationships help ensure consistent product quality, timely deliveries, and competitive pricing. When choosing a supplier, buyers must consider factors like reliability, cost, and service support.

In this guide, we’ll walk you through everything you need to know about choosing the best wholesale steel strapping suppliers in Australia. From understanding the types of steel strapping to selecting the right tools and accessories, and evaluating suppliers, this guide is designed to help you make informed decisions about your steel strapping needs.

Steel strapping comes in various forms, each designed to serve a specific purpose. The key distinction lies between regular duty and high tensile steel strapping.

High tensile steel strapping is the ultimate solution for heavy loads, offering superior strength and durability. It is ideal for industries that need to secure massive loads, such as construction, mining, and manufacturing.

Regular duty steel strapping, on the other hand, is suitable for lighter applications like bundling smaller items or securing medium-weight products.

Juhong's UltiMax™ High Tensile (HT) Series steel strapping is engineered for the most demanding heavy-duty applications, directly comparable to the performance standards set by industry leaders like Signode Magnus and USLM.

Our strapping is characterized by its High Tensile Strength combined with High Elongation, offering superior shock resistance and load integrity for critical shipments.

| Series | Standard | Tensile Classification | Tensile Strength(MPa) |

| Terra / Ridge | GB/T 25820-2025 | Regular Tensile | 650-750Mpa |

| Pivot / Duro | GB/T 25820-2025 | Medium Tensile | 830-930Mpa |

| Nexa | GB/T 25820-2025 | High Tensile & Low Elongation | 980Mpa |

| Ultimax | ASTM D3953 or EN 13246 | High Tensile & High Elongation | 1020Mpa |

When comparing steel metal strapping to plastic alternatives like PET (polyester) and PP (polypropylene),the strength and resilience of steel strapping stand out. Plastic strapping may suffice for lighter packaging tasks but cannot match the tensile strength or reliability of steel strapping when dealing with heavy loads or rough handling.

If you’re wondering how steel strapping compares with PET strap, or if you’re looking to understand the distinction between PET and PP (polypropylene) strapping materials, we’ve got you covered. For a deeper dive, be sure to check out our articles on Steel Strapping vs. Polyester Strapping and The Difference Between PET and PP Strapping .

This is a versatile option widely used across industries for general-purpose packaging. Its 2-inch width is a common size, providing optimal balance between strength and ease of use. The black finish not only offers a professional appearance but also provides additional corrosion resistance.

Zinc coating offers an extra layer of protection, making it ideal for use in harsh environments. The galvanized steel strapping is corrosion-resistant and perfect for outdoor storage, ensuring the strap does not weaken or rust when exposed to moisture or extreme weather conditions.

Unlike regular steel strapping, perforated straps are designed for non-tensioning bundling or fixed mounting. These straps are ideal for applications where the load doesn’t require tensioning but still needs secure fastening.

Produced by heat-treating the steel (annealing) to create a protective,At the same time, the formation of bluing film on the surface of the steel strapping and then coated a layer of water wax to form the double protection. It has excellent anti-corrosion performance to ensure long-lasting durability. Smooth and burr-free edges ensure safe handling.

It is cold rolled , process without heat treated and metal surface (silver-gray), It offers high cost performance and reduces procurement costs.

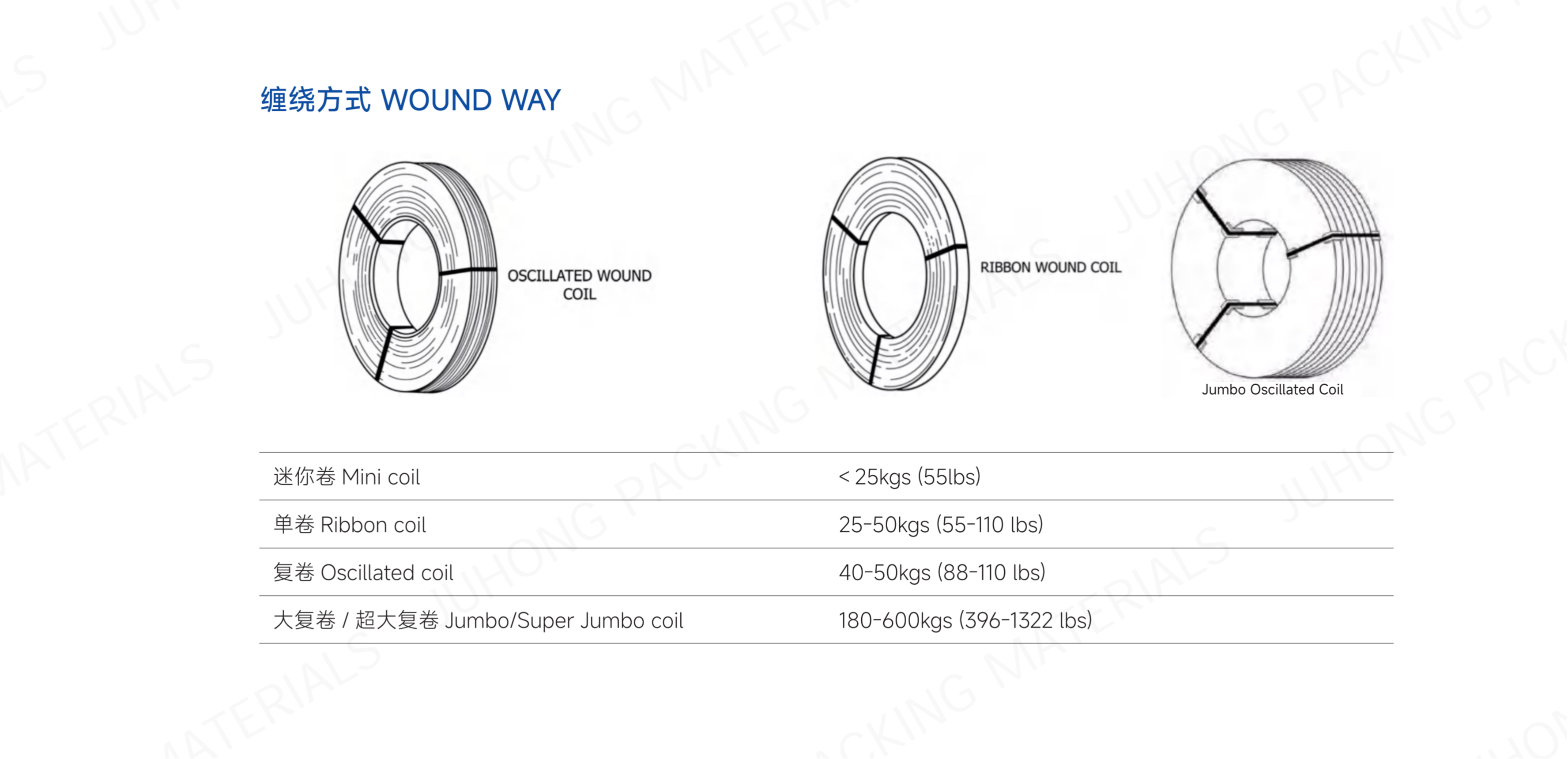

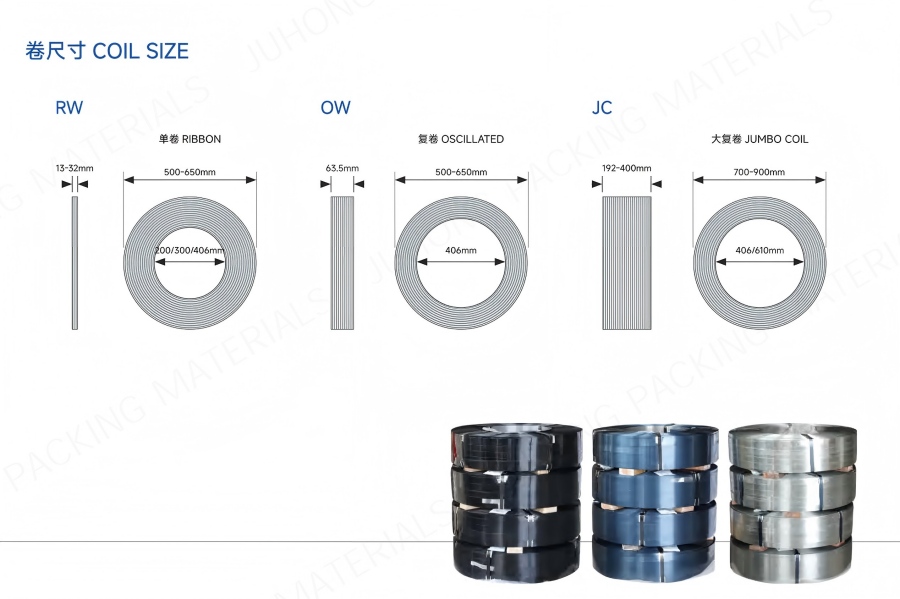

Ribbon wound

Oscillated wound

Jumbo wound

When selecting steel strapping, the type of coil winding affects the way the strapping is handled, especially when using automated equipment.

Ribbon wound coils are commonly used for manual strapping, while oscillated wound coils are better suited for automated dispensers. The choice of coil type can influence both the speed and efficiency of the strapping process, especially for high-volume operations. Jumbo wound coil steel strapping with a width 32mm is usually 180kgs/280kgs/360kgs/400kgs/500kgs/1000kgs.Jumbo is generally suitable for steel strapping machine.

To effectively secure loads, steel strapping requires the right tools and accessories. Here are the essential components that make up a complete steel strapping system:

1.Tensioner for Steel Strapping: The tensioner is the most important tool in manual steel strapping. It tightens the steel strap around the load to create maximum tension, ensuring the product remains secure during transportation.

2.Steel Strapping Cutter: A reliable cutter is essential for cutting through steel straps quickly and safely. When selecting a steel strapping cutter, safety is paramount. Choose cutters that are designed for high-tensile steel to avoid damage to the tool and ensure efficient cutting.

3.Strapping Seals: The snap-on seals and thread-on seals are designed to secure the ends of the steel strapping. Snap-on seals are quick and easy to use, while thread-on seals offer a more secure attachment. Both are necessary for ensuring the strapping holds firmly in place.

For businesses dealing with high-volume applications, strapping machines and dispensers are not just conveniences—they are necessities for scaling operations. These automated systems handle large quantities of strapping quickly and consistently, drastically reducing manual labor and maximizing operational efficiency. The key to seamless, high-speed automation often lies not only in the machine but also in the consumables that feed it.

This is where Juhong's expertise in specialized components ensures your system runs flawlessly. Our automatic and semi-automatic tools are engineered to work perfectly with precision-made, patented magazine seals. Unlike loose seals, these pre-stacked steel clips feed continuously into the strapping tool’s chute, ensuring minimal downtime and delivering maximum joint security for your heavy loads.

When you choose Juhong for your steel strapping supplies, you are partnering with an industry authority. Juhong Packing Materials was the chief drafter of the Chinese national standard, GB/T 39040—2020: Steel seals and edge protectors for packaging. This unique accreditation means our entire range of seals—including our patented magazine seals—is engineered to the highest possible standards for strength, material consistency, and reliability, offering Australian buyers unparalleled quality assurance in their automated strapping processes. The integration of our high-quality steel strapping equipment with precision seals guarantees a streamlined, powerful, and secure packaging line.

For a seamless and efficient strapping process, buying a full steel strapping kit is recommended. A complete kit will include everything you need: strapping material, seals, tensioners, cutters, and dispensers. Having all the tools and consumables from one supplier ensures compatibility and minimizes the risk of delays caused by mismatched products.

When looking for steel strapping, you can either work with suppliers or go directly to manufacturers. Both options have pros and cons. Steel strapping manufacturers like Juhong offer the advantage of higher-quality control and often lower prices due to direct access to the production process. However, local suppliers and distributors may offer faster delivery times and support for smaller orders.

To choose the best steel strapping supplier, you must consider several factors:

•Quality Certifications and Consistency: Suppliers with proper certifications ensure their products meet industry standards, providing consistency in quality.

•Stock Availability and Lead Times: A supplier with reliable stock and short lead times helps avoid operational delays, especially for businesses with high-volume needs.

•Competitive Pricing on Steel Strapping for Sale: Wholesale pricing is essential for businesses looking to purchase in bulk. A competitive supplier will offer discounts based on volume, making it more cost-effective in the long run.

For businesses looking for steel strapping near me, it’s crucial to find suppliers with a robust distribution network. Large suppliers and manufacturers often have warehouses in major Australian cities like Sydney, Melbourne, and Brisbane, making it easier to access steel strapping quickly. Local suppliers can also offer quicker response times and personalized service, which is invaluable for businesses with urgent needs.

At Juhong Packing Materials, we take pride in producing high-quality steel strapping that meets international standards. Our manufacturing processes focus on durability, reliability, and performance. With advanced technology and strict quality control measures, we ensure that every batch of steel strapping delivers the strength and flexibility that Australian industries require.

We specialize in high tensile steel strapping , zinc-coated steel strapping, and Painted Steel Strapping Band Black,all of which are designed to withstand harsh conditions and heavy loads. Our strapping materials are engineered to last, ensuring your shipments are secure from start to finish.

Juhong offers wholesale pricing for bulk orders, allowing businesses to save on costs while getting high-quality steel strapping. Our large-scale production ensures that we can accommodate large orders without compromising on quality. Additionally, we offer customization options for steel strapping, such as specific sizing or even branding on the seals, giving businesses a personalized solution.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Est. 1997, China's only integrated producer of steel/polyester straps, PE film & seals. Annual output: 60K tons steel straps, 300M seals, 12K tons polyester/film. Triple ISO certified, Jiangsu High-Tech. ROHS/REACH/AAR compliant. Exports to 50+ countries. Trusted by 3000+ global clients including Fortune 500. 27 Years of Quality Focus, Delivering the Comprehensive Strapping Solution.Contact us to get Free sample now!

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America