Views: 0 Author: Sunny Yu Publish Time: 2025-10-20 Origin: Site

In today’s heavy-duty industrial, packaging and logistics market, securing large, heavy loads is not a matter of using the “best-possible plastic strap” and hoping for the best—it requires high performance materials built for extreme conditions. That’s where high-tensile steel strapping comes in. At Juhong Packing Materials, we often say: “If your load could move, shock, shift or deform during transport, you need a steel strap designed for performance—not just a strap that ‘works’.”

High-tensile steel strapping is designed to minimize stretch, resist shock loads, and maintain tension under demanding circumstances. Because of these qualities, choosing the right manufacturer becomes critical. That’s why we have compiled a ranking of the top 8 global manufacturers of high-tensile steel strapping . We’ll share their unique strengths, what to look out for, and how you as a buyer can leverage this knowledge.

This article is framed from our perspective so that you:

understand the high-tensile steel strapping market better,

know how to evaluate manufacturers,

and see how Juhong fits into this ecosystem as a strong alternative.

Let’s dive in.

High-tensile steel strapping is a premium-grade securing solution, distinguished by a specialized heat-treatment process. This critical step significantly boosts its tensile strength, break resistance, and ability to absorb shock, making it fundamentally stronger than standard-duty strapping.

At Juhong Packaging, we supply this robust material for the most demanding applications where failure is not an option. Its superior strength makes it the preferred and often mandatory choice for securing heavy pallets, irregular items, and massive loads, especially for rigorous transport like railroad shipments. From industrial equipment and construction materials to shipping steel itself, our high-tensile strapping delivers the reliable, heavy-duty performance your business depends on.

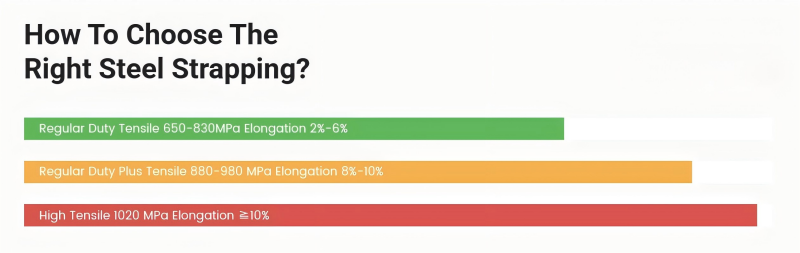

Here are key performance criteria:

Break Strength — the maximum tensile load the strap can bear before failure. A higher break strength means you can secure heavier loads or provide greater safety margin.

Tensile Strength — reflects the steel’s inherent strength per unit area. For example, one firm reports 1020 N/mm² for its high-tensile strap.

Elongation — a strap that can absorb movement, vibration, dynamic shock is valuable. For example, a strap with ≥10 % elongation is well suited for such conditions.

Surface & Coating — finish matters for corrosion resistance, friction, tool compatibility (waxed, zinc-coated, painted).

Compatibility with Tools & Systems — high-tensile strap must work with the right tensioners, sealers, automatic equipment. If tools are not matched, you risk under-tensioning or strap damage.

When you search “high-tensile steel strapping manufacturer”, these are the qualities you’re ideally looking for.

Selecting the right manufacturer of high-tensile steel strapping isn’t just about grabbing the lowest price. The right choice impacts: safety, load integrity, cycle time, cost of failure, and logistics performance.

Here are factors you should evaluate:

Make sure the manufacturer provides detailed specs (width, gauge, break load, tensile strength, finish) and ideally supports third-party certification.

Look for reference to recognized standards (ASTM, AAR, ISO). Many high-tensile straps will cite these to show reliability.

High-tensile steel strap is heavy, bulky, and often used globally. A manufacturer with local stock, international shipping options, tool support and regional presence is stronger. This matters if you serve multi-region logistics.

If the strap is high-tensile, your tensioners and sealers must handle the higher load. Otherwise you risk strap damage or poor joint strength. Some manufacturers offer matched tools and straps which is a plus.

Beyond the coil price, you must consider tool compatibility, freight cost, failure risk, downtime, scrap, and replacements. A more expensive strap may yield lower overall cost if failure risk drops.

Below are the eight manufacturers ranked in the order you provided. For each one we’ll highlight: a brief overview, why they deserve their place, key product strengths, and what to watch (for buyers).

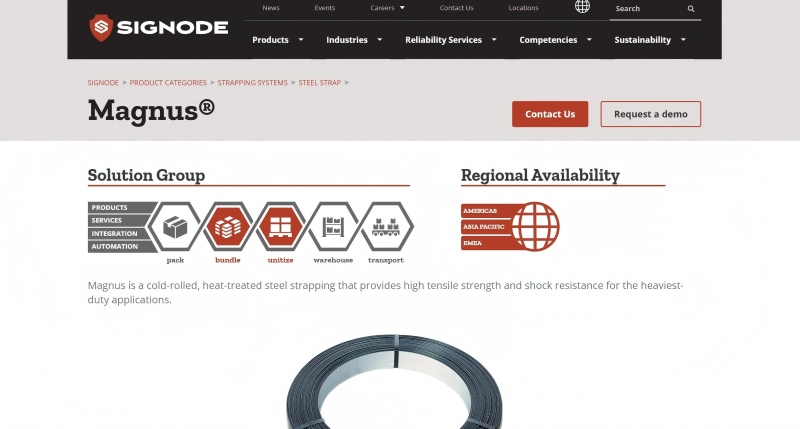

Website: www.signode.com

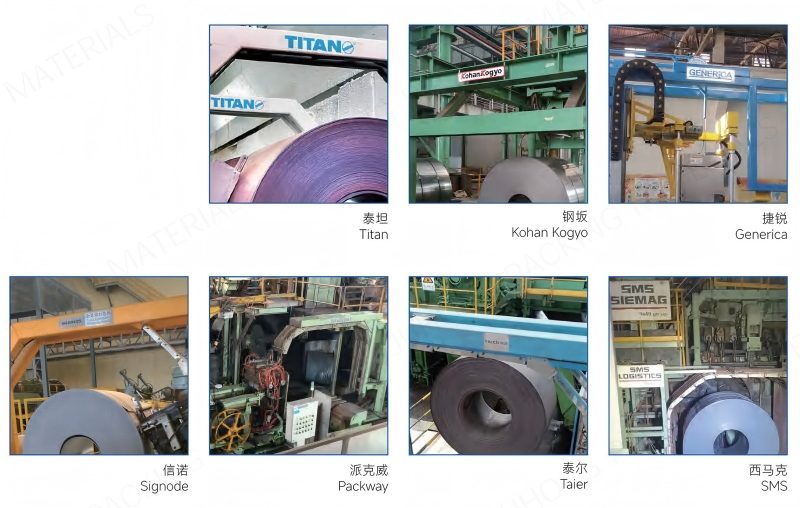

Overview: A global leader in protective packaging and strapping systems, with an extensive range of steel strapping including high-tensile lines (Magnus®) and full system/tool integration.

Why #1: Their Magnus® range is explicitly positioned for the highest duty applications: cold-rolled, heat-treated medium-carbon steel; break strengths up to 13,200 lbs (58,667 N) in listed specs.They offer multiple finishes (painted & waxed, zinc & waxed, blued & waxed) to support different environments. The detailed specification tables show width, gauge, break strength and coil wound data.

Key Strengths:

Very high break loads for heavy loads

Global presence and strong service support

Tool/strap system synergy

What to watch: Because they are premium, you might pay a premium; ensure their regional lead-time and stock suit your geography.

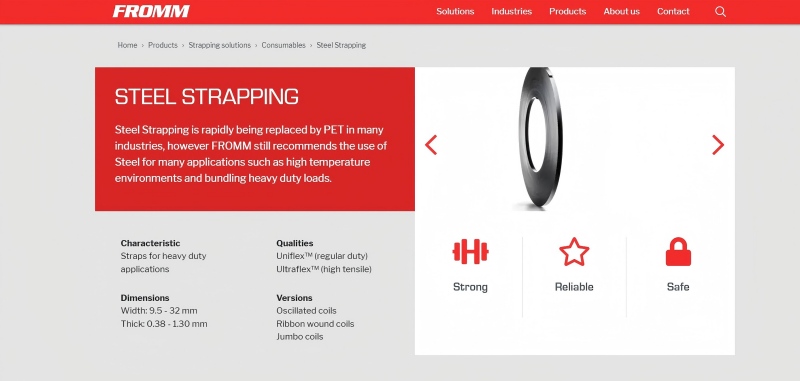

Website: www.fromm-pack.com

Overview: FROMM is a Swiss-based packaging materials and systems company with a well-developed steel strapping offering, including high-tensile grades under the Ultraflex™ moniker.

Why #2: Their combination of both strap and tool system means you get more than just a coil—they support the lifecycle. They also emphasize heavy-duty/industrial applications. Their tool specification mentions handling up to 1100 N/mm² strap.

Key Strengths:

Well-integrated tool + strap offering

Suitable for heavy industrial loads

What to watch: The “high-tensile” portion must be clearly specified—some standard straps may also be offered under the same brand. Confirm you’re ordering the high-tensile grade.

Website: www.shop.cyklop.com

Overview: Cyklop is a European packaging materials company (historical from 1912) with a modest but capable steel strapping range, including heavy duty and wide-width offerings.

Why #3: For users with varied load types (construction materials, metal, timber) their flexibility in widths/thicknesses is useful. Their UNIFLEX steel strap series supports widths up to 32 mm and heavy duty tension.

Key Strengths:

Good width/thickness flexibility

European manufacturing standards

What to watch: Their publicly available data for the absolute top break loads is less detailed than top tier brands; you may need to request custom spec sheets for extreme loads.

Website: www.maillis.com

Overview: Maillis is a renowned packaging consumables and systems group with steel strapping offerings focused on metal, container and heavy‐industrial sectors.

Why #4: Their ability to provide full packaging systems (not just strap) is beneficial for customers bundling large items like metal containers or structural segments.

Key Strengths:

Industry focus on heavy packaging segments

System-oriented (strap + machine + service)

What to watch: When your requirement is for extremely high tensile strength (for example break loads above 50 kN), ensure their “high-tensile” strap matches the spec and is separate from standard duty.

Website: www.titanstrapping.com

Overview: German manufacturer specialising in high-strength steel strapping and systems, with a strong technical specification component.

Why #5: Their “Megaflex II” high-tensile steel strap is specified with tensile strength up to 980 N/mm² and breaking loads up to ~31,100 N (~7,000 lbf) for certain sizes. They also emphasize very high elongation (≥16 %) for dynamic loads.

Key Strengths:

Technical excellence (very high tensile & elongation metrics)

Good for extremely dynamic or heavy load scenarios

What to watch: Premium specification means higher cost; also ensure your tooling supports these higher loads. Shipping/regional service may be weaker outside Europe.

Website: www.steelstrapping.com

Overview: Based in Vietnam, Sam Hwan serves the Asia-Pacific region with steel strapping including high-tensile grades.

Why #6: For buyers sourcing in Asia, their regional base and cost-competitiveness stand out.

Key Strengths:

Regional cost advantage in Asia

Good range including high-tensile grades

What to watch: High-tensile grades may have fewer global certification references; verify the specification sheet for your load requirements and international shipping conditions.

Website: www.samuelpackaging.com

Overview: A U.S.-based company known primarily for packaging systems, but also supplying steel strapping including high-strength options.

Why #7: Strong service network in North America, good for customers based in U.S./Canada or with North-American distribution.

Key Strengths:

Good regional presence for North America

Package-ready systems + strap

What to watch: For global shipping or ultra-heavy loads, confirm their high-tensile strap’s break load and global logistics support compared to top tier global specialists.

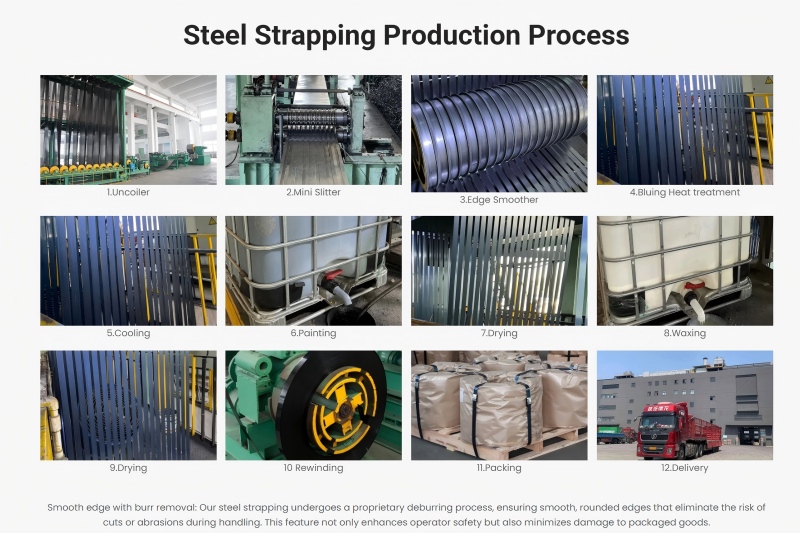

Overview: That’s us. Juhong Packing Materials (www.jsjhpackaging.com) is an emerging globally-oriented supplier based in China, offering high-tensile steel strapping along with other packaging consumables.

Why #8 : Founded in1997, Juhong Packing Materials boastsover 27 years of production experience

in packaging consumables, including steel strapping.

We are located in Changzhou, Jiangsu Province (approximately 200 km from Shanghai Port), and our factory covers more than 20,000 m² with multiple production lines for steel strap, PET strap, wrapping film and steel seals.

Juhong steel strapping that work with hand,pneumatic,or fully -auto mathines-delivering fast ,strong and reliable performance.

Key Strengths:

Customization: widths, gauges, coatings (wax, zinc, blue-anneal) tailored to load/application

Competitive cost and good responsiveness for Asia or globally

One-stop integrated manufacturing: We are among the very few Chinese companies that integrate the production of high-tensile steel straps and polyester straps, PE wrapping film and steel seals all under one roof.

Ability to act as partner in specifying correct strap for your application

What we recommend you consider:

Ensure that the high-tensile strap we supply is clearly labeled with break strength / tensile strength / elongation specs & finish.

Confirm tooling compatibility if you are moving from a different manufacturer.

Ask for samples and test on your actual loads.

Call to Action: If you are looking for high-tensile steel strapping, we invite you to contact us at Juhong Packing Materials via www.jsjhpackaging.com. Let’s discuss your load profile, the strap spec you need, and how we can deliver a tailored solution.

Now that you have this ranked list and insight into each manufacturer’s strengths, how do you move from information to decision? Here’s a practical roadmap:

Ask yourself:

What is the bundle weight or load weight?

Will there be dynamic forces (vibration, shock, lift/unload)?

Is the bundle irregular, round, heavy metal, containerised, palletised?

Are there environmental factors (temperature, humidity, corrosion risk)?

These answers help you determine what break load, strap width/gauge, coating and elongation you need.

Break load: must exceed your maximum anticipated load with safety margin.

Tensile strength: pick a high-tensile grade if dynamic forces exist.

Elongation/shock resistance: important if the load will move or vibrate.

Finish/coating: if exposed outdoor or in corrosive environments.

For example, if you need break load ~30 kN + elongation ≥10 %, you might gravitate toward TITAN or Signode or Juhong . If you are cost sensitive and based in Asia, you may look at Juhong or Sam Hwan.

Ask each manufacturer for:

Datasheet with width, thickness, tensile strength, break load, elongation, finish

Sample coil for your in-house testing

Tool compatibility recommendation (tensioner/sealer)

Test the strap on your actual load scenario (tension it, apply vibration/impact if possible).

What is lead time?

Are tool/spare parts supported?

How is international shipping handled (if needed)?

Don’t just compare cost per kg of strap. Include:

Cost of tool changes or incompatibility

Freight/shipping cost of heavy coils

Cost of downtime or damage if strap fails

Service or spare parts availability

Once you pick the manufacturer & strap spec, integrate:

Tool calibration & training (since high-tensile strap may require different tension settings)

Specification documentation in your packaging/manufacturing process

Monitoring & inspection regimes (check strap tension after load, check for strap damage)

Supply chain management (ensure consistent sourcing, test variance between lots)

It’s not enough to just pick a good strap today—you should also consider where the industry is headed. Here are key trends we at Juhong observe:

With global supply chains moving larger pallets, heavier equipment, and more aggressive packaging optimisation, the demand for higher-strength straps continues. Manufacturers like Juhong are already specifying 980 N/mm² tensile strength.

End-of-line packaging lines increasingly require strap + machine + software integration. Manufacturers that offer full systems (strap, tensioner, sealer, automation) will be advantaged.

Even steel strap—often seen as “heavy”—must now meet environmental expectations. Ultra-high strength means less material for the same load, reducing resource usage. Some manufacturers highlight recyclable raw material and waste-reduction efforts.

With manufacturing hubs shifting and logistics cost rising, there is increasing value in sourcing from regional manufacturers or partners who can deliver locally. That’s why Asian manufacturers like Sam Hwan and Juhong are gaining interest.

As loads vary more (e.g., exposure to chemicals, marine transport, welding operations), strap finish/coating becomes more customised (zinc, wax, painted, blue tempetured ).

We offer a value-driven, performance-focused alternative in the high-tensile steel strapping arena. Here’s how we present our proposition:

We manufacture and supply high-tensile steel strapping in a variety of widths, gauges, coatings and finishes, tailored to heavy-duty applications.

We provide responsive service and customisation, especially for buyers in Asia or seeking alternative sourcing.

We support your application with specification advice, sample coils, testing guidance, and full packaging consumable support (beyond just strap).

Competitive cost: Because we are based in China and optimise our manufacturing & supply chain, we can offer cost-effective high-tensile strap without compromising spec.

Customisation: Many large manufacturers specialise in standard sizes; we flex for special sizes/coatings if your load demands.

Global readiness: While global giants dominate, we are equipped to support international buyers, shipping, logistic coordination and specification support.

Partnership mindset: We act as your packaging partner, not just supplier. We help you pick the right strap + system for your load, rather than selling you a “one size fits all” coil.

Juhong Packing Materials' Brochure.pdf

Juhong Packing Materials' Brochure.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

Juhong packing meterials ISO 45001.pdf

Juhong packing meterials ISO 45001.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel Strapping SGS Certification.pdf

Juhong Steel Strapping SGS Certification.pdf

“If you’re bundling heavy loads, large equipment, steel coils or large merchant shipping pallets — don’t compromise by using under-spec strap. Contact Juhong Packing Materials at www.jsjhpackaging.com. Let’s talk about your load, your environment and deliver the right high-tensile steel strapping solution for you.”

The world of high-tensile steel strapping is not glamorous—but it is absolutely crucial. When a strap fails or loosens, the consequences range from damaged cargo, freight delays, safety incidents, to increased cost. That’s why your choice of manufacturer matters—material spec, tool matching, service network and cost must all align.

Here are the key take-aways for you:

Define your load and risk profile first (weight, dynamics, environment).

Use minimum specification thresholds for break load, tensile strength, elongation and finish.

Short-list manufacturers (use the ranking above as a start) that meet or exceed your spec.

Request datasheets and sample coils and test on your actual load scenario.

Confirm tool compatibility, global supply/lead-time, logistics and service support.

Consider total cost of ownership—not just strap price.

Stay aware of industry trends — heavier loads, automation, sustainability, custom coatings.

By following that approach, you’ll be well-positioned to select a high‐tensile steel strapping manufacturer that supports your packaging performance today—and scales with your business tomorrow.

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America