Views: 0 Author: Sunny Yu Publish Time: 2025-09-18 Origin: Site

Ever tried to keep a heavy pallet, a coil of steel, or a stack of timber secured with the wrong strap? It’s a headache—and a costly one. High tensile steel strapping is designed to do one job very well: hold heavy loads reliably under shock, vibration, and long transit times. If you ship heavy goods, or your customers demand export-grade packaging, switching to the right high tensile strap is like upgrading from a neighborhood sedan to a commercial truck—built for the job.

Name3

Regular duty metal straps are fine for light-to-medium pallets. High tensile metal straps are produced from cold-rolled carbon steel (with controlled chemistry and heat treatment when required) to achieve much higher breaking strength per cross-section. That means fewer straps per load, less labor, and a smaller chance of load shift or strap failure.

The regular duty plus steel strap has a tensile strength of approximately 880 N/mm² with a maximum elongation of 8%. This type of strap is suitable for applications that require higher strength and provides more reliable securing performance.

The high tensile steel strap has a tensile strength above 980 N/mm². This type of strap is suitable for industries that require extremely high strength and ensures secure fastening even under extreme conditions.

The high tensile high elongation steel strap has a tensile strength above 1000 N/mm² with an elongation of 12% (based on ASTM and European standards). This type of strap is suitable for special applications and provides extremely high strength and elongation, ensuring secure fastening in various conditions. We are the only manufacturer in China producing this type of high tensile and high elongation steel strap, offering competitive prices and good-quality products.

Yes, high tensile costs more per meter. But you often need fewer bands, you reduce product damage in transit, and you save labor (faster tensioning/sealing). Over time, fewer claims + fewer replacements = better total cost of ownership. Think “buy better, ship safer, save later.”

ASTM D3953 is the go-to specification for flat steel strapping and seals in many export and industrial contexts. It defines types, finishes, widths, minimum breaking strengths, and minimum seal joint strength for many strap sizes and duties—so buyers and suppliers share the same technical language. The standard lists tables for Regular Duty, Regular Duty High-Strength, Heavy-Duty and Extra-Heavy steel straps and specifies seal classes and finishes.

ASTM gives numeric minimums for breaking strength by width/thickness combinations and also specifies acceptable seal types and minimum seal joint strengths for certain extra-heavy applications. In short: ASTM tells you what numbers the strap and the seal must hit for a given duty level—so a buyer can specify “ASTM D3953 heavy-duty 3/4″ × 0.035″” and expect a certain performance level.

ASTM Standard for packaging steel straps in the United States.pdf

ASTM Standard for packaging steel straps in the United States.pdf

Juhong Packing Materials is a one-stop packing materials manufacturer: steel strapping (including high tensile steel strapping), PET / PP strapping, seals and tools. The steel line includes blue/black painted & waxed straps, galvanized (zinc coated) straps, regular duty, regular duty plus, and high tensile options. That full lineup means Juhong can match strap type to the customer’s exact application and standards needs.

PET Strap

Magazine seals

Galvanized steel strap

Steel Strip Specification Table of Juhong Packing Materials.pdf

Steel Strip Specification Table of Juhong Packing Materials.pdf

For customers with extreme requirements, Juhong’s premium lines (e.g., UltiMax high tensile steel straps) are engineered to deliver elevated tensile grades. Certain Juhong high tensile products are described as engineered for demands around 1080 N/mm² tensile grades—this level places them squarely in the high-performance bracket suitable for heavy coils, steel beams and heavy machinery. If your spec calls for “high tensile” or explicit ASTM table numbers, Juhong provides product variants that meet those break strength targets.

Not every shipment faces the same environment. For inland, dry shipments a painted/blue & waxed strap may be perfect; for sea freight or humid routes a zinc coated steel strapping is often the safer choice because the zinc layer protects the steel from corrosion. Juhong offers both painted and galvanized finishes so customers can choose the optimal protection level for their route and product.

Blue steel strapping

Black steel strapping

Galvanized steel strapping

Two numbers matter most: breaking strength (how much load it resists before failing) and elongation (how much it stretches before breaking). High tensile straps target higher breaking strength with controlled elongation so tension is maintained. But remember: the strap is only one half of the system—seal joint strength and the quality of the seal/sealless joint matter just as much.

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong Steel strapping SGS EU standard Test Report.pdf

Juhong packing meterials ISO 45001.pdf

Juhong packing meterials ISO 45001.pdf

Juhong packing meterials ISO 9001.pdf

Juhong packing meterials ISO 9001.pdf

Juhong packing meterials ISO 14001.pdf

Juhong packing meterials ISO 14001.pdf

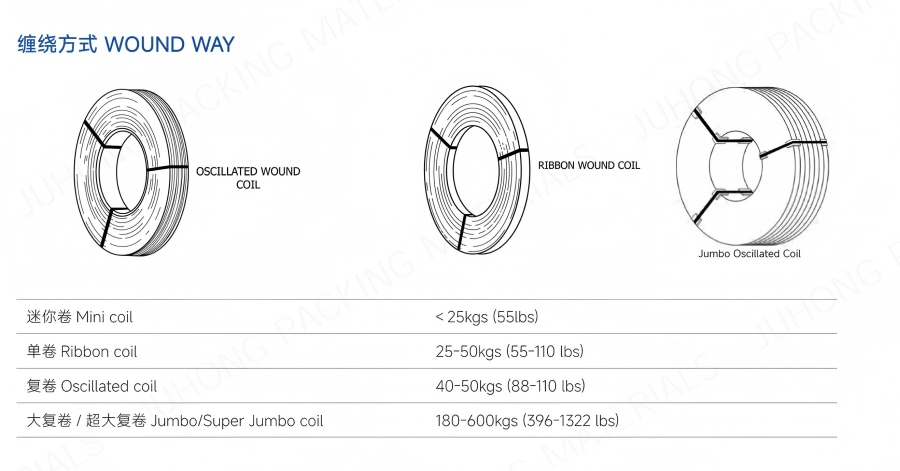

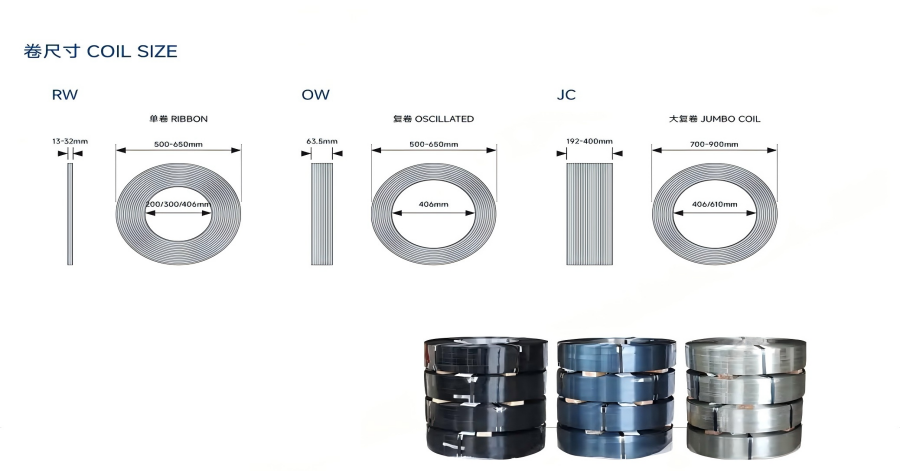

Juhong supplies Jumbo、oscillated 、ribbond wound,Jumbo wound coil steel strapping with a width 32mm is usually 180kgs/280kgs/360kgs/400kgs/500kgs/1000kgs.

Oscillate wound coil steel strapping with a width 12.7mm/16mm/19mm is usually 40-50kgs per roll.12-18 rolls per pallet.

Ribbon wound coil steel strapping with a width 12.7mm/16mm/19mm is usually 25-30kgs per roll. 25mm steel strapping: 36-40kgs per rolls.32mm steel banding: 45-50kgs per roll.around 1 ton per pallet.

Zinc coating (galvanization) shields the steel with a sacrificial layer that slows rust formation—vital for sea freight or humid conditions. Paint plus wax adds barrier protection and improves shelf life for inland or dry climates. If you’re packing high-value or export freight, specifying zinc coated steel strapping or a heavy paint finish cuts the risk of rust stains, strap degradation, and customer complaints.

Who uses high tensile steel strapping? Typical industries include:

Steel and metal coils (primary use case: coil securement)

Construction materials (beams, rebar, timber bundles)

Paper & pulp (heavy rolls)

Aluminium and non-ferrous ingots

Glass and ceramics (when rigid restraint is needed)

High tensile straps are the go-to for any B2B shipment where failure is not an option.

Here’s a compact checklist every procurement or operations manager should use:

Identify load type & weight per strap — heavier loads need higher break strengths.

Pick the right width × thickness that corresponds to ASTM table values (if you’re specifying ASTM).

Choose finish: galvanized (zinc) for corrosion risk; painted/ blue &waxed steel strapping for general protection.

Match the seal style: open/snap, thread-on/closed, push-type ,magazine seals or sealless; seals must be rated for strap thickness/width.

Confirm tool compatibility: manual sealless tools, pneumatic machines, or automatic strapping machines—Juhong provides compatible tooling and seals.

Sealless joints (on machine) can provide higher consistency; clip/seal systems are flexible for manual or mixed workflows. The important thing is that the joint’s measured strength must be acceptable relative to band strength—otherwise the joint becomes the weak link. Ask for joint strength test reports when you order.

Juhong run batch tests for breaking strength, elongation, coating adhesion and straightness. For export or high-risk loads, they provide test certificates showing strap mechanical properties and often the coating specification. Juhong can pack test certificates with the shipment.

Want a sample? Ask for a cut-to-length sample and matching seal, plus a certificate of tensile/break test. If you need a spec sheet to embed in an RFQ or contract (ASTM callouts, coil type, ), request the PDF spec and test report from Juhong’s export team. Juhong’s site shows full product categories and contact points for B2B inquiries.

If your business ships heavy or high-value goods, high tensile steel strapping isn’t optional—it’s a risk-management tool. Juhong offers a full range (high tensile, galvanized/zinc coated, painted & waxed, blue & waxed steel strapping,matched seals and tooling), Use the checklist above when you write purchase specs, and always request test data when you need to prove performance.

How to Choose the Right Steel Strapping: A Comprehensive Buyer’s Guide

Steel Vs. Polyester (PET) Strapping: 2026 Industry Comparison by Juhong Packing Materials

Top 10 Tali Strapping Band Besi Manufacturers & Suppliers in Indonesia (2026 Industry Guide)

Top 12 Best Steel Strapping Manufacturers in Germany: 2025 Expert Guide

The Ultimate Guide To The Top 7 Steel Strapping Manufacturers in South America